Water seal safety evaluation of multi-period adjacent underground caverns based on discrete fracture network

-

摘要:

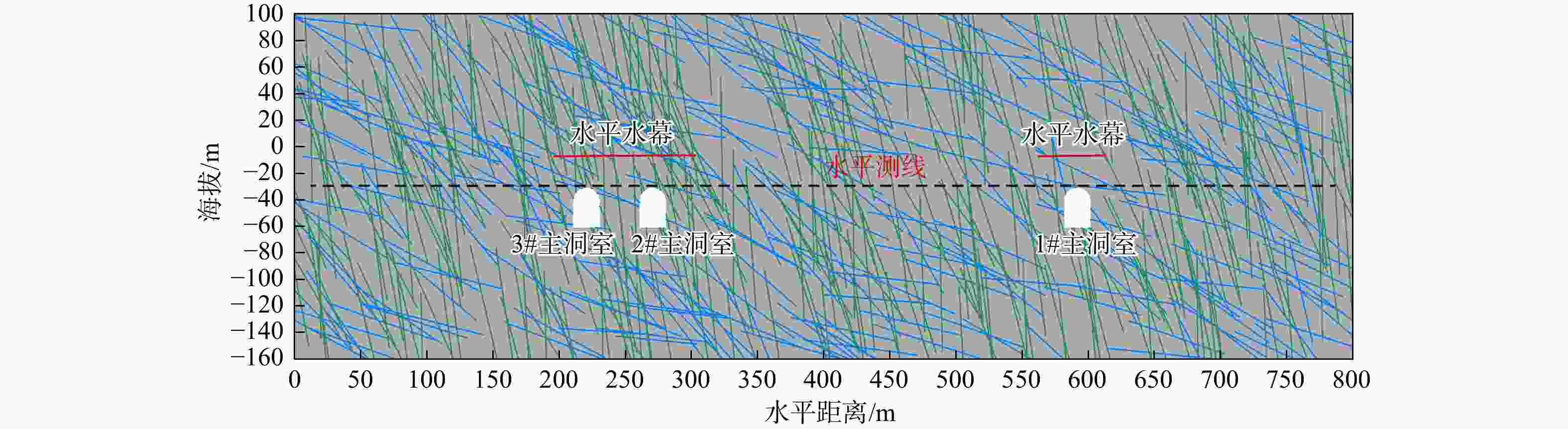

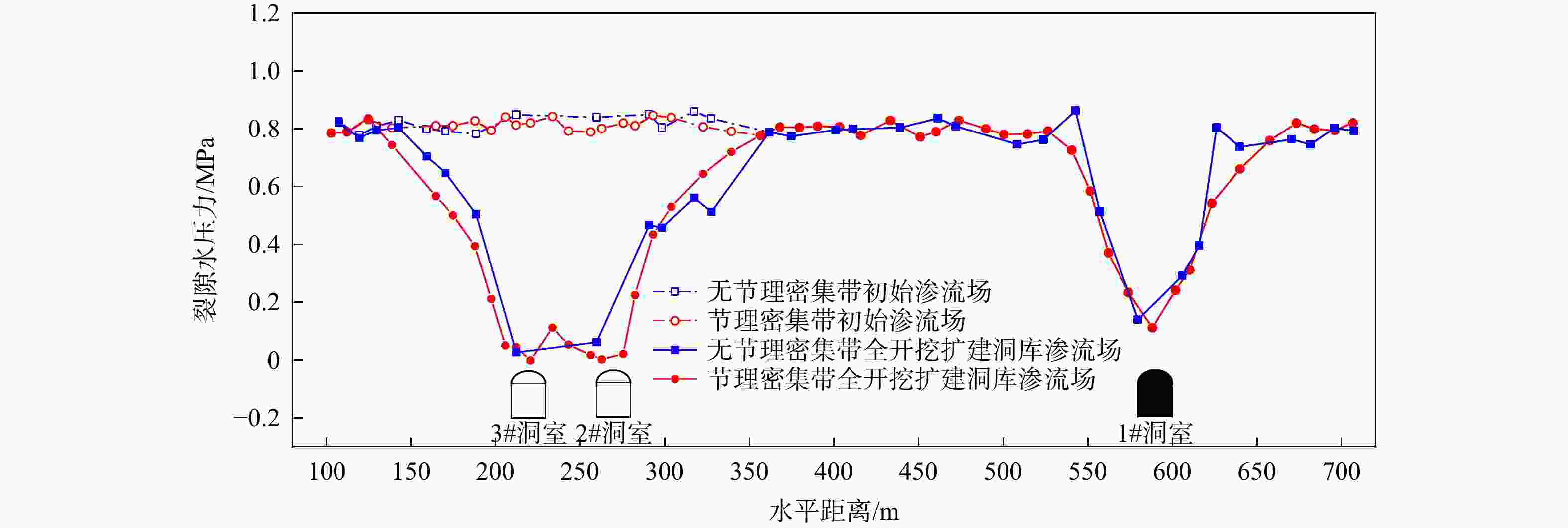

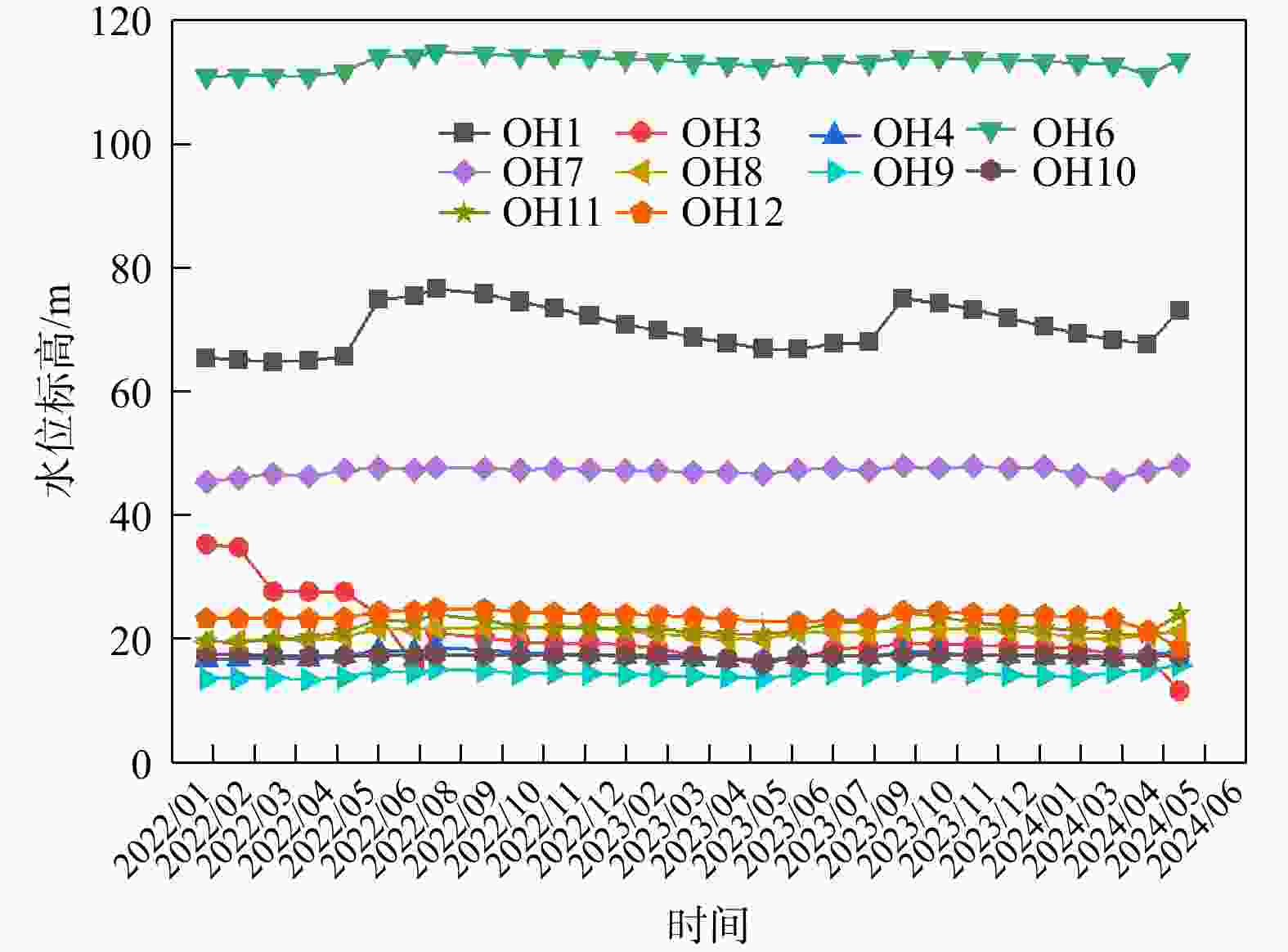

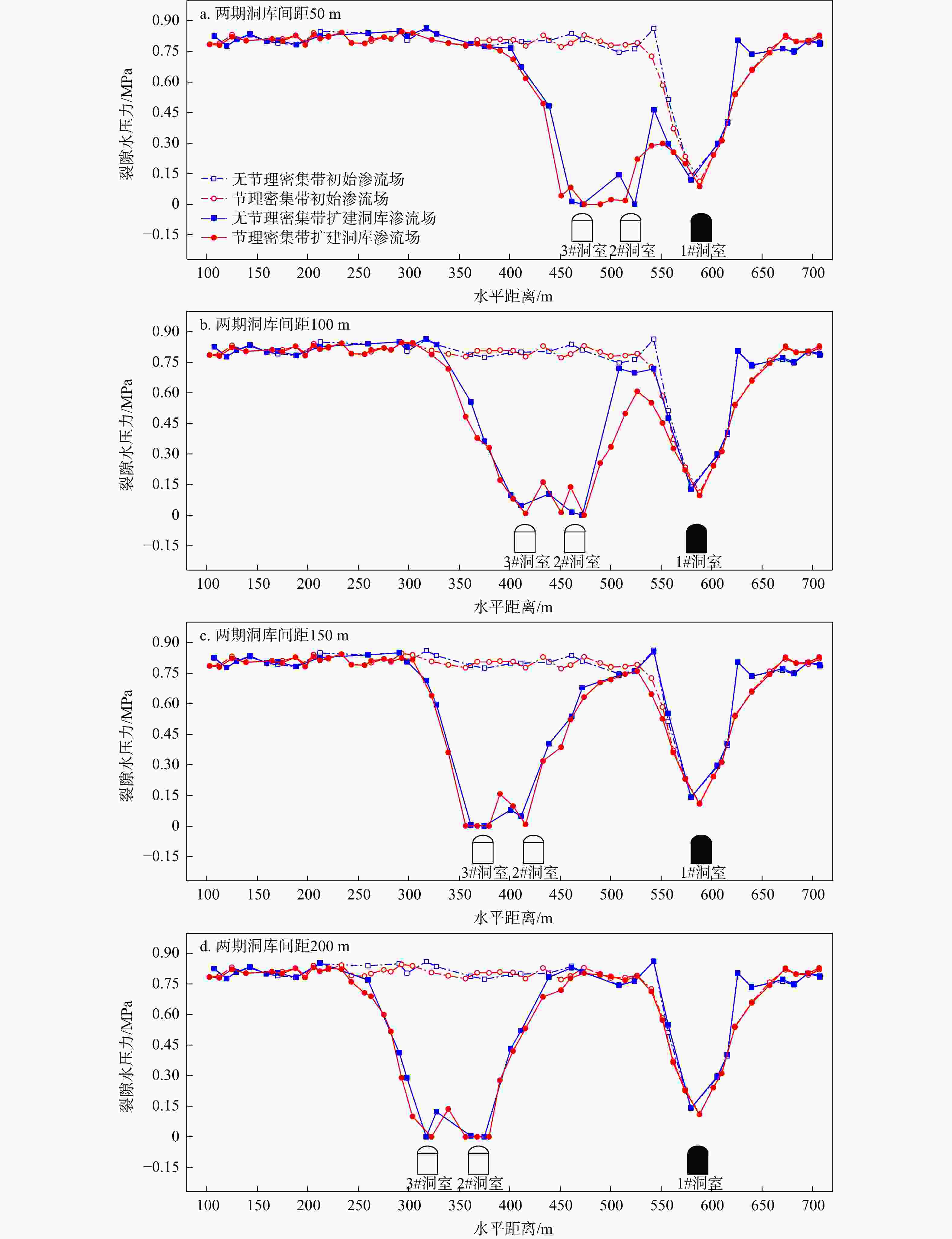

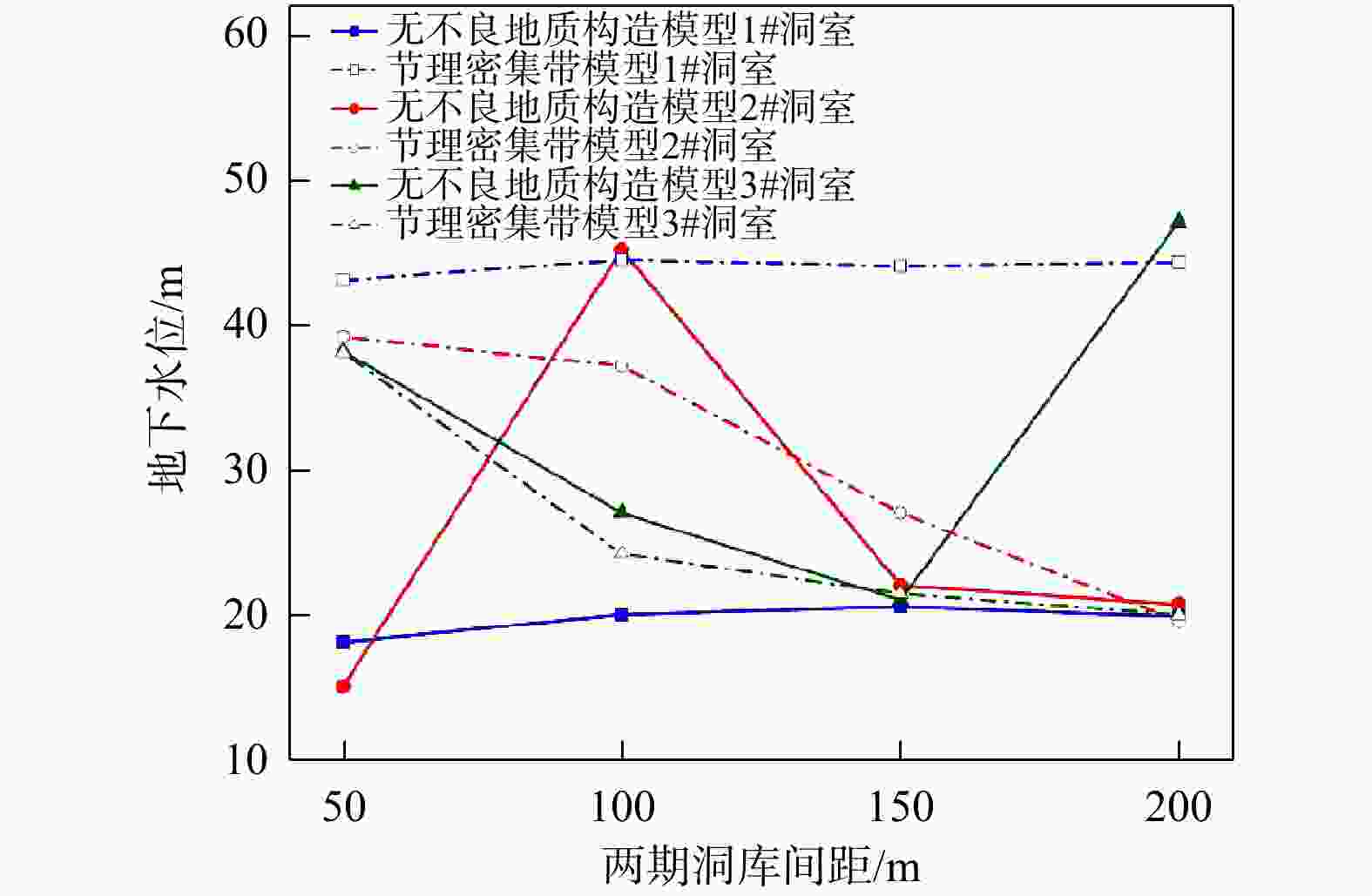

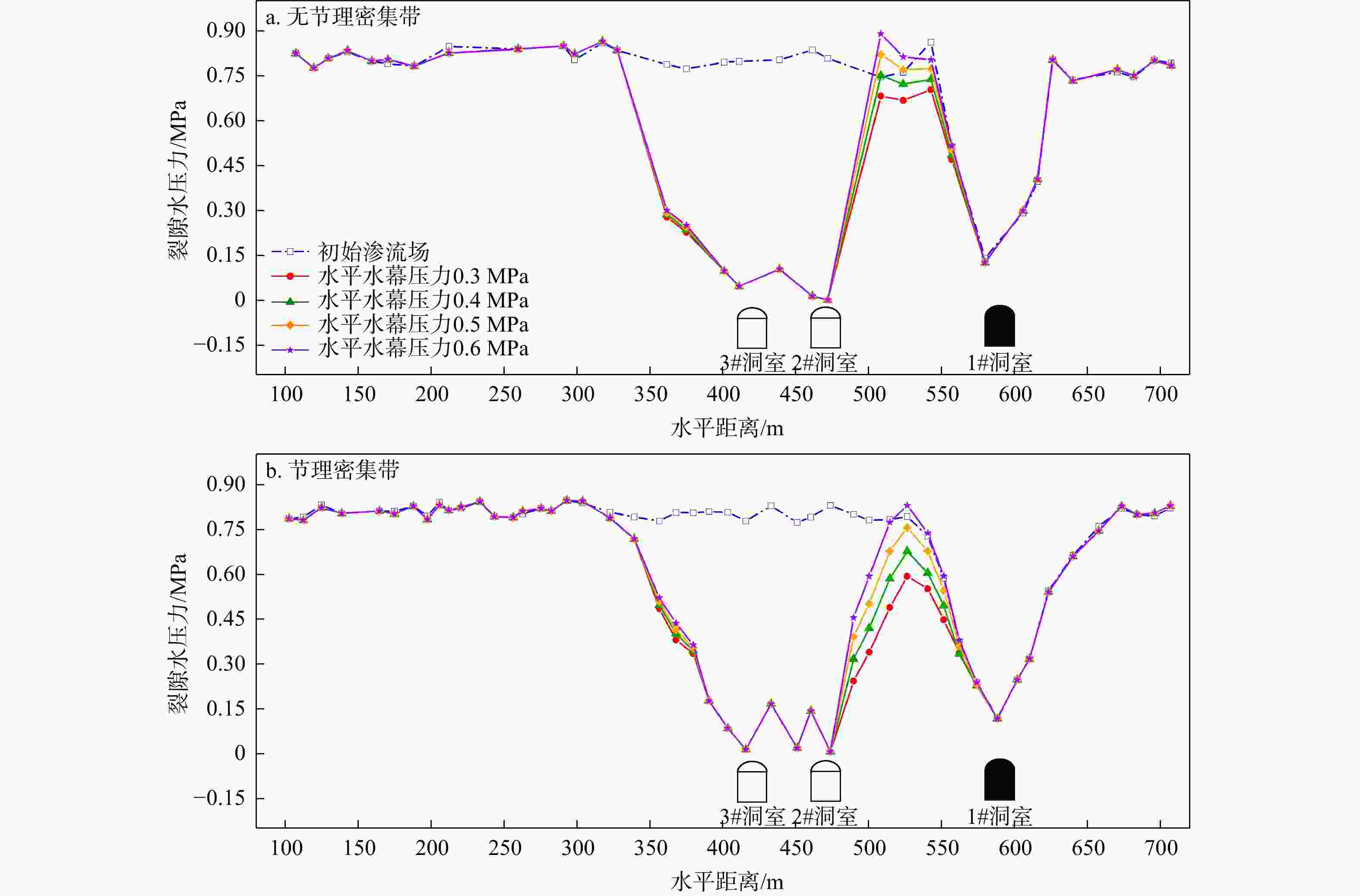

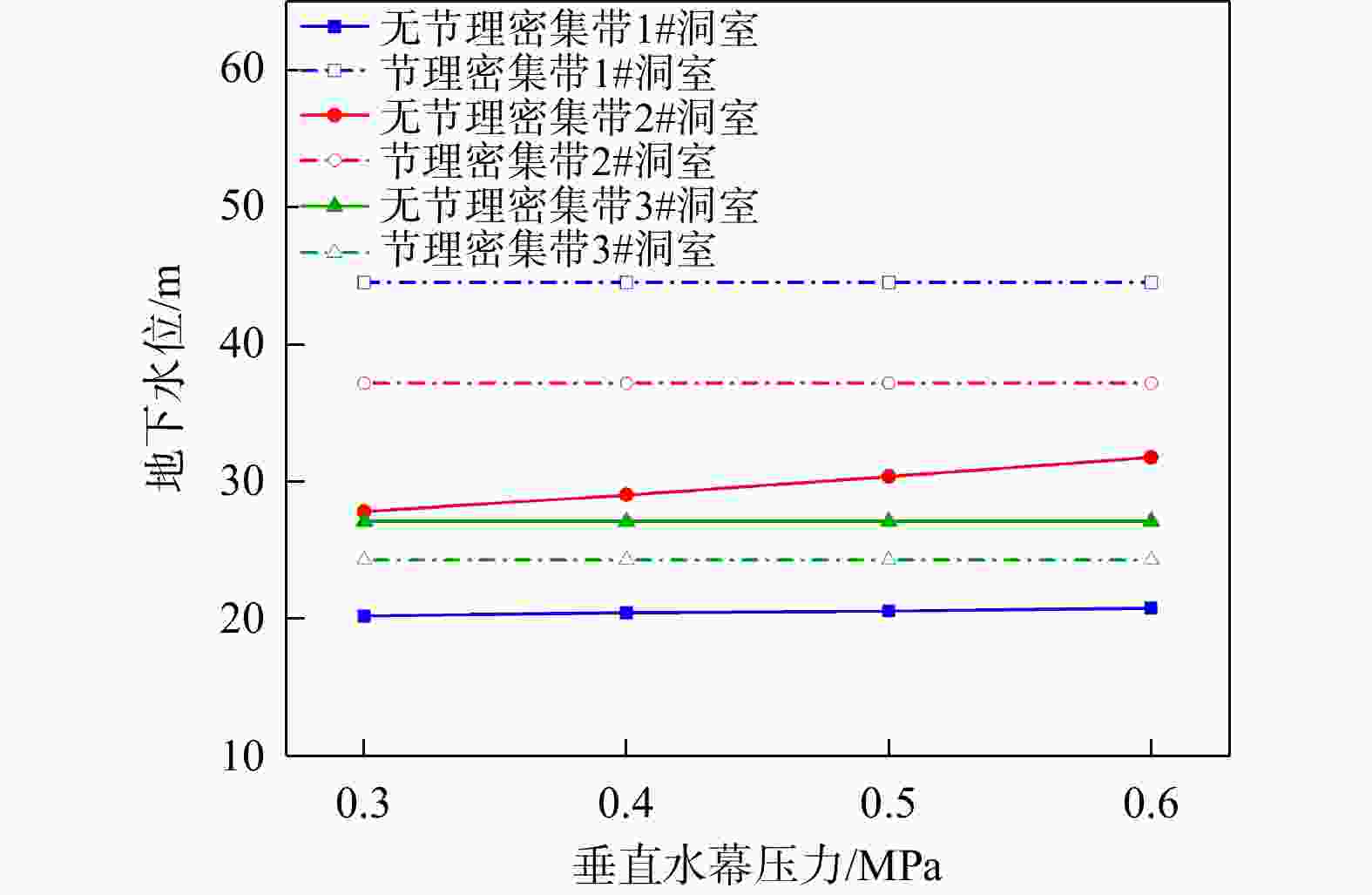

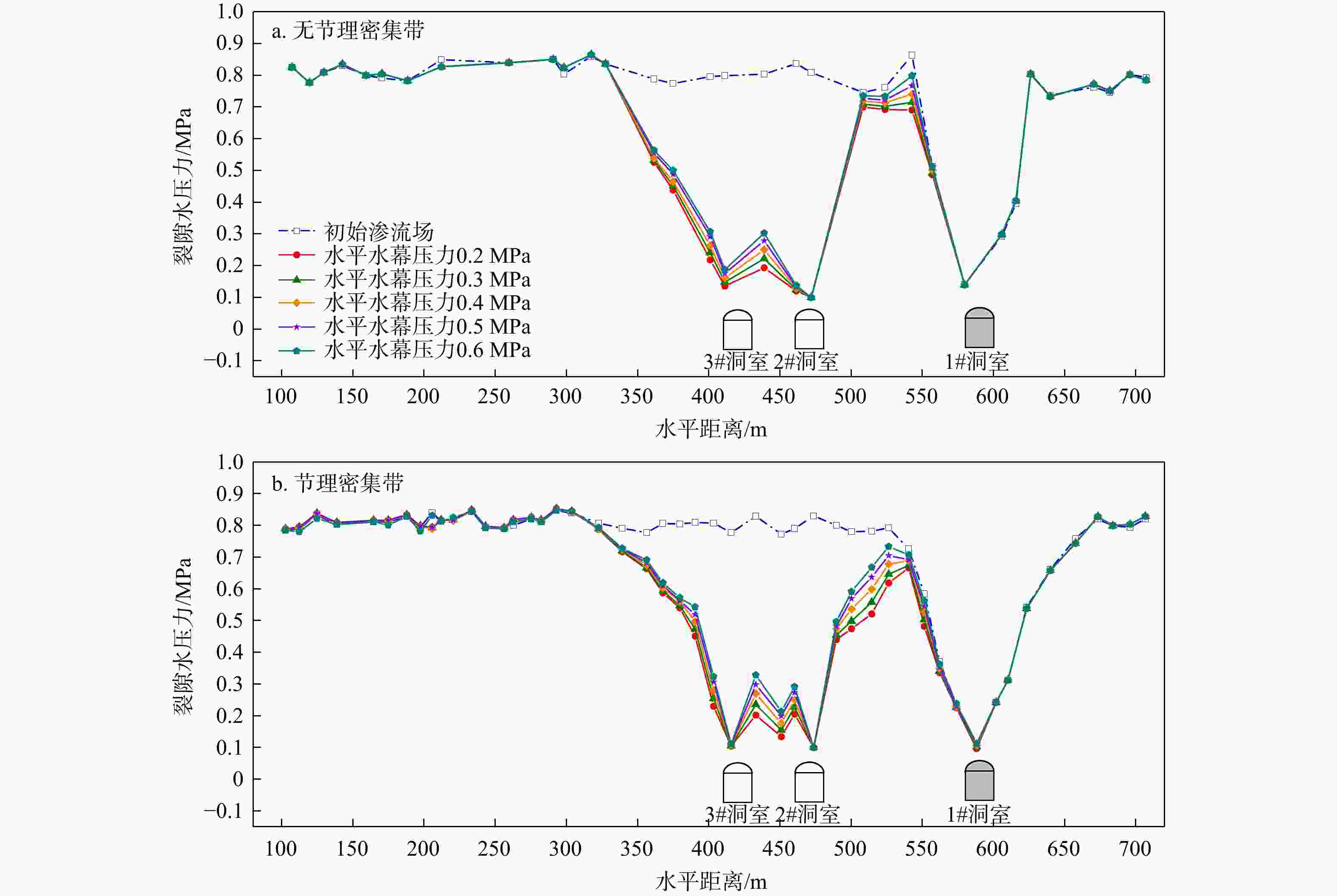

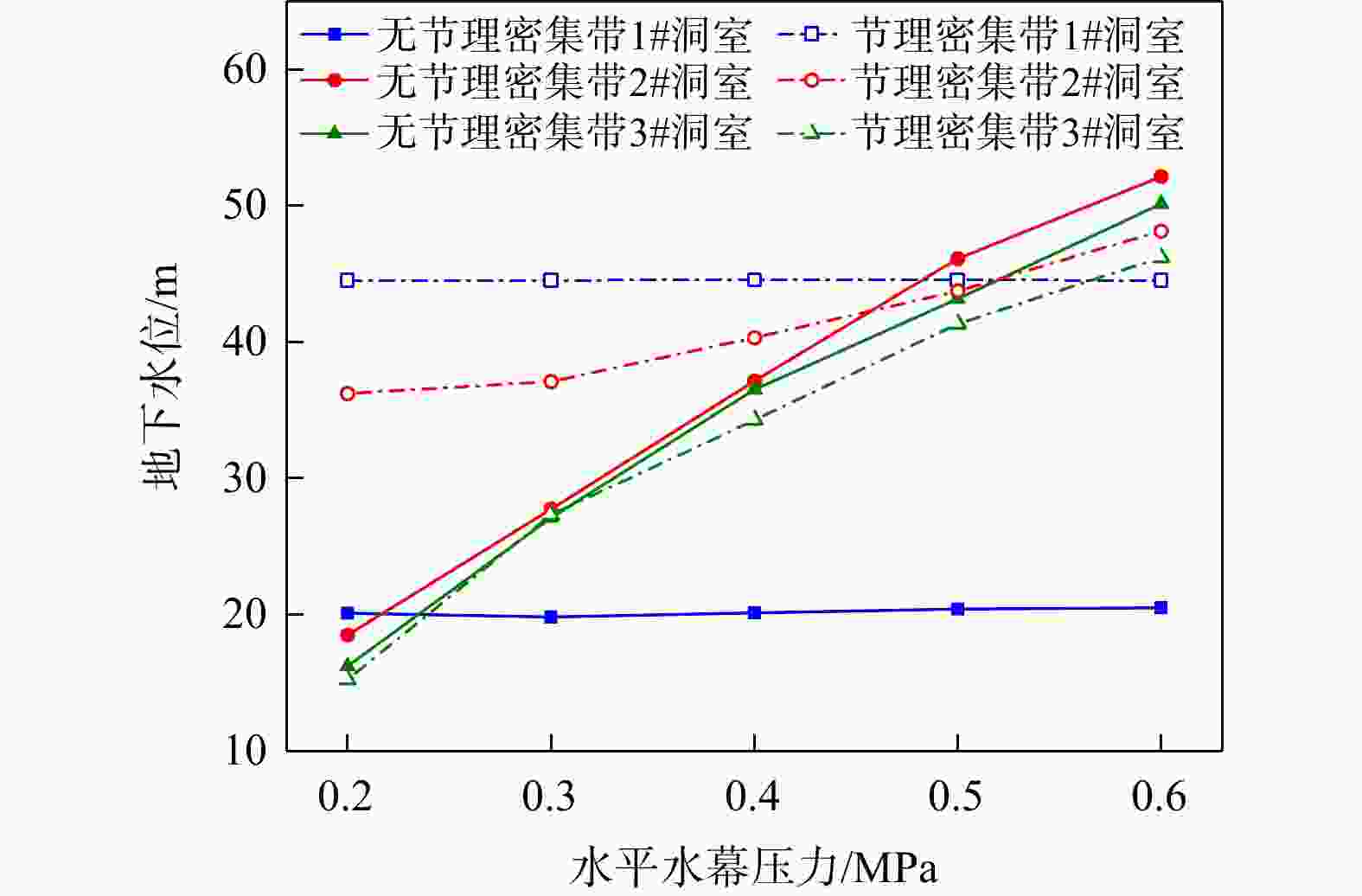

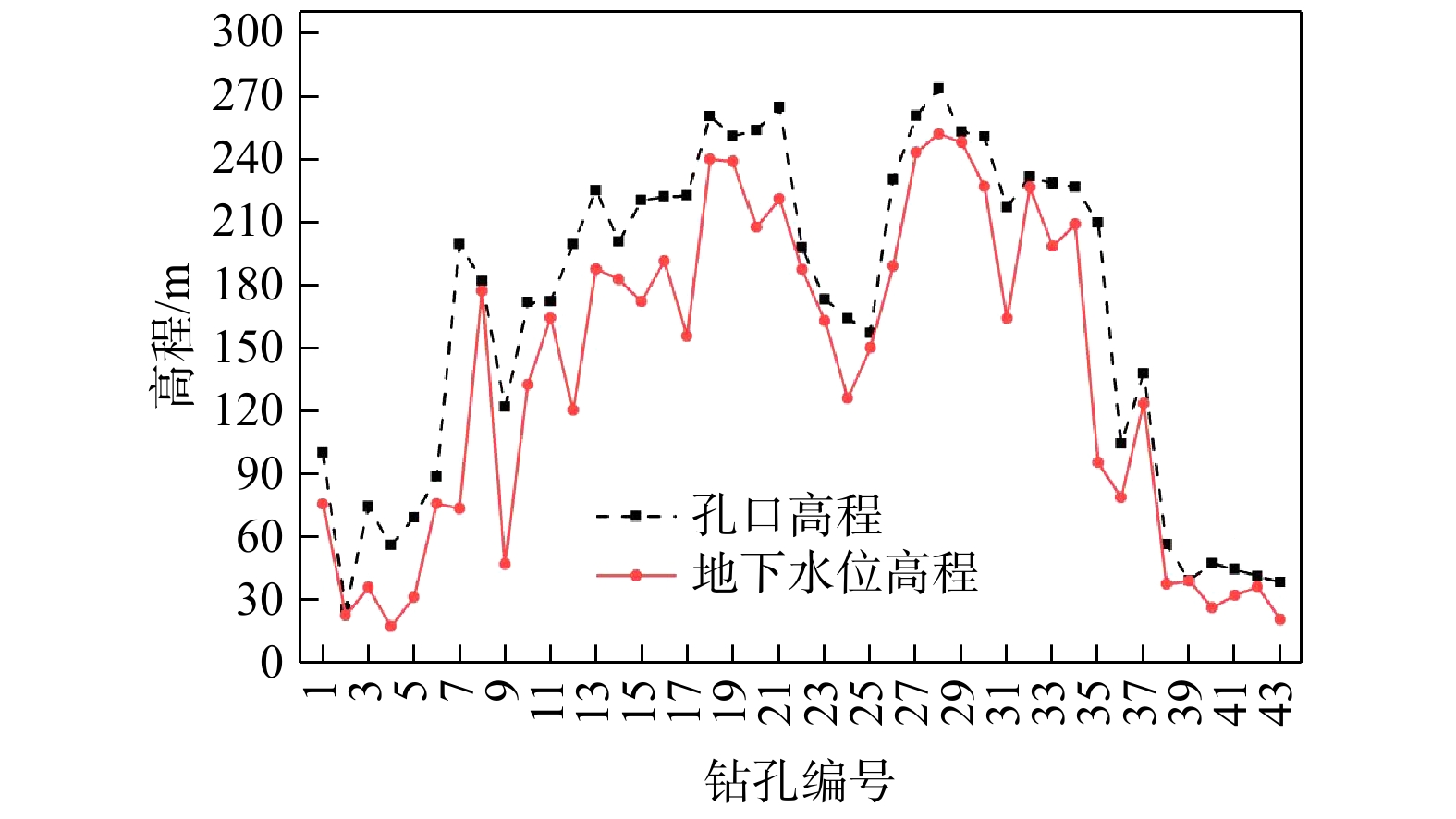

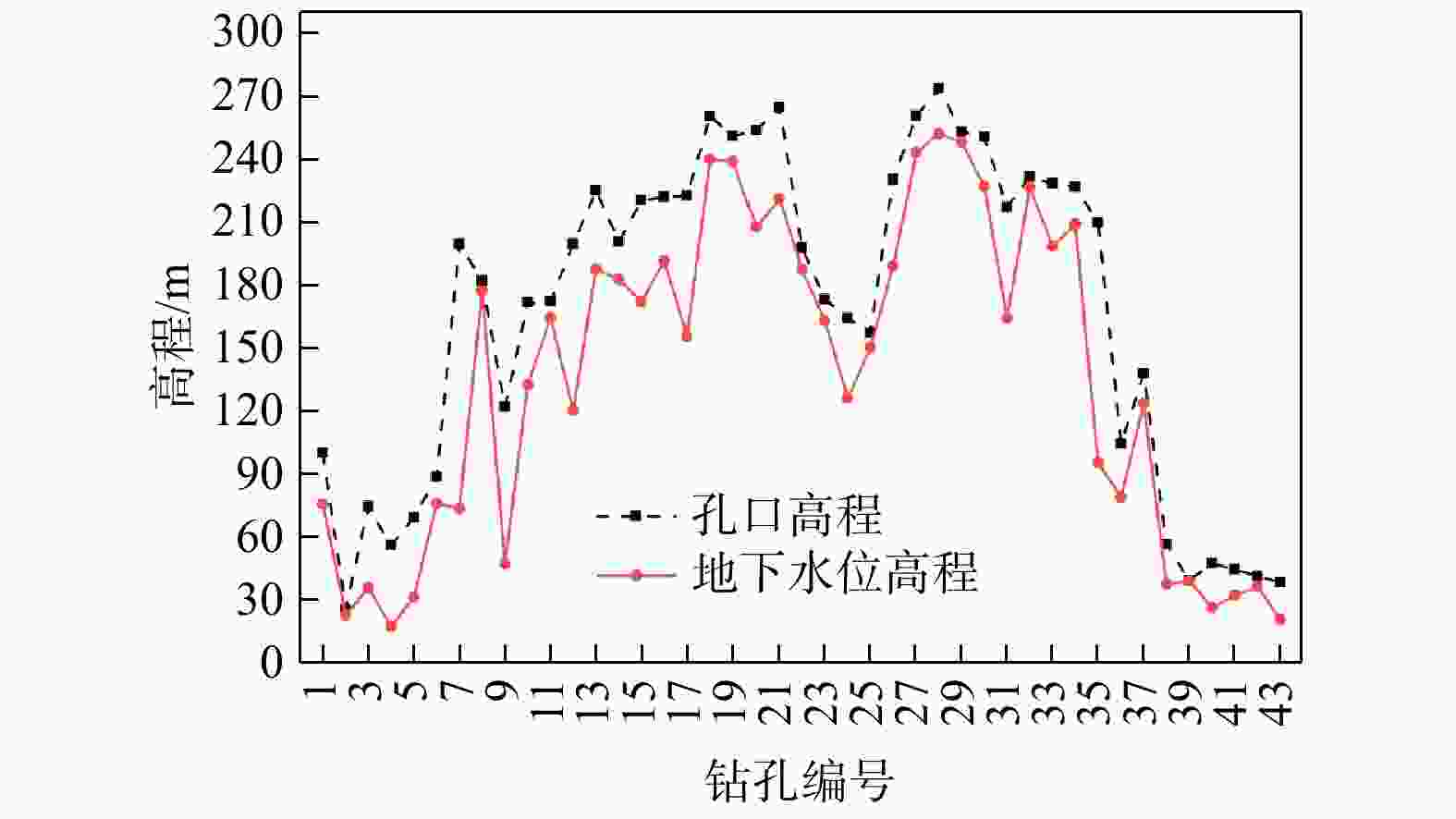

我国很多大型地下洞库都采用多期建设的方法,而扩建地下洞库可能会对邻近运营的同类洞库渗流场产生一定影响,导致油气外泄等一系列安全事故,因此保障扩建后的水封安全至关重要。以某大型地下洞库扩建项目为依托,分析库区地质条件和裂隙分布特征,考虑连通两期洞库的节理密集带,基于现场水文试验成果,反演裂隙等效开度,并基于离散裂缝网络(DFN)建立两期地下洞库简化模型,研究了扩建地下洞库的水封安全,同时进行了扩建地下洞库对运营洞库水封安全影响因素的研究。研究表明:本项目扩建洞库对运营洞库的水封安全没有影响,但节理密集带会严重影响扩建洞库的水封安全;且通过对扩建洞库对邻近运营洞库水封安全影响因素的研究,确定了洞库最小安全间距为200 m,垂直水幕压力和水平水幕压力设置为0.4 MPa时,可以保障扩建洞库与运营洞库的水封安全。因此,对于大型地下洞库扩建项目,节理密集带是影响水封安全的关键因素,确保最小安全间距和适当水幕压力设置,能有效保障扩建洞库与运营洞库的安全性。研究成果为大型地下洞库扩建工程可能遇到的水封安全问题提出了理论依据。

Abstract:Objective Many large underground caverns in China will adopt a multi-stage construction method, and the expansion of underground caverns may have a certain impact on the seepage field of similar caverns near operation, potentially leading to a series of safety accidents such as oil and gas leakage. Therefore, ensuring the safety of the water seal after expansion is of critical importance.

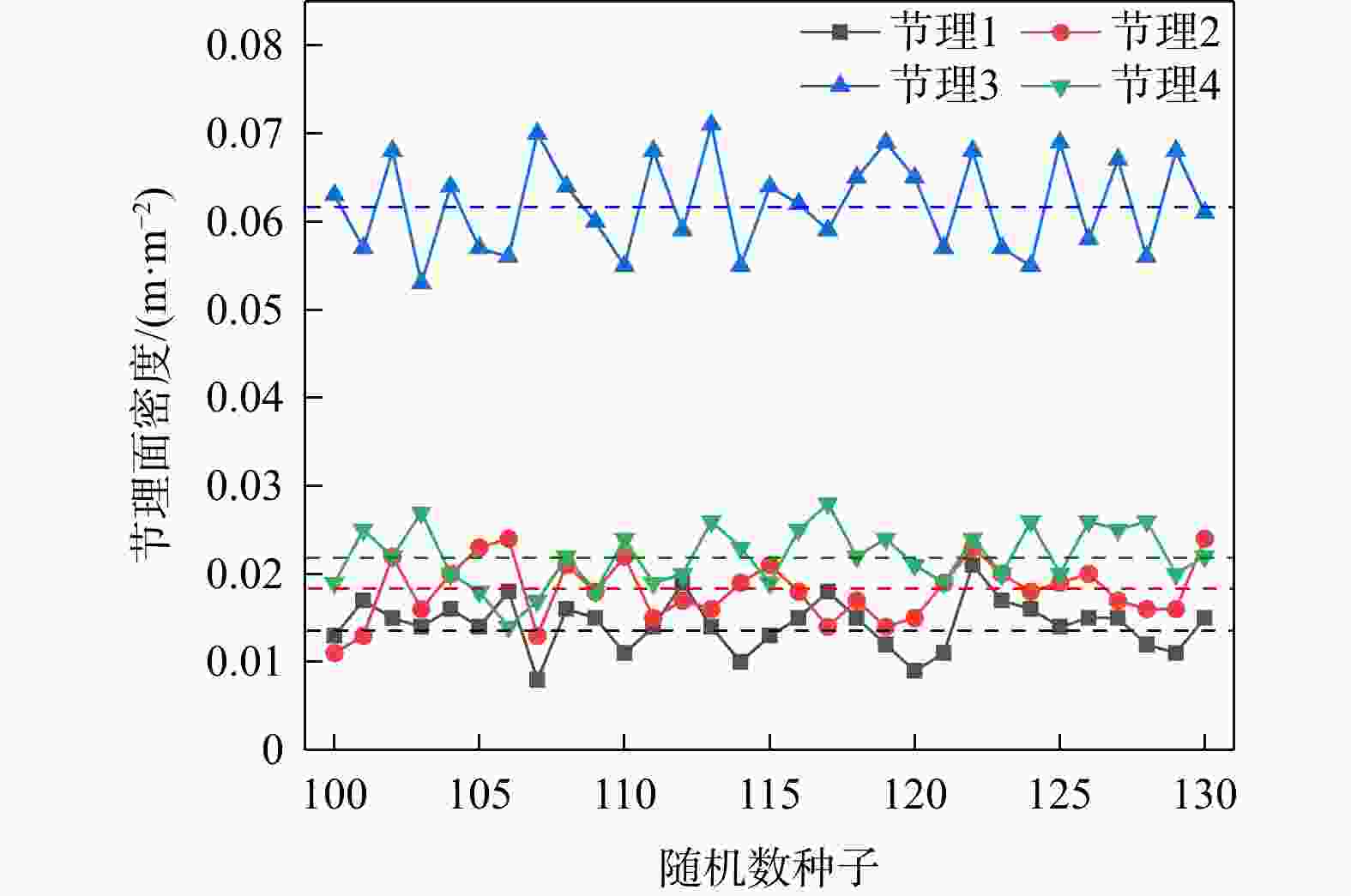

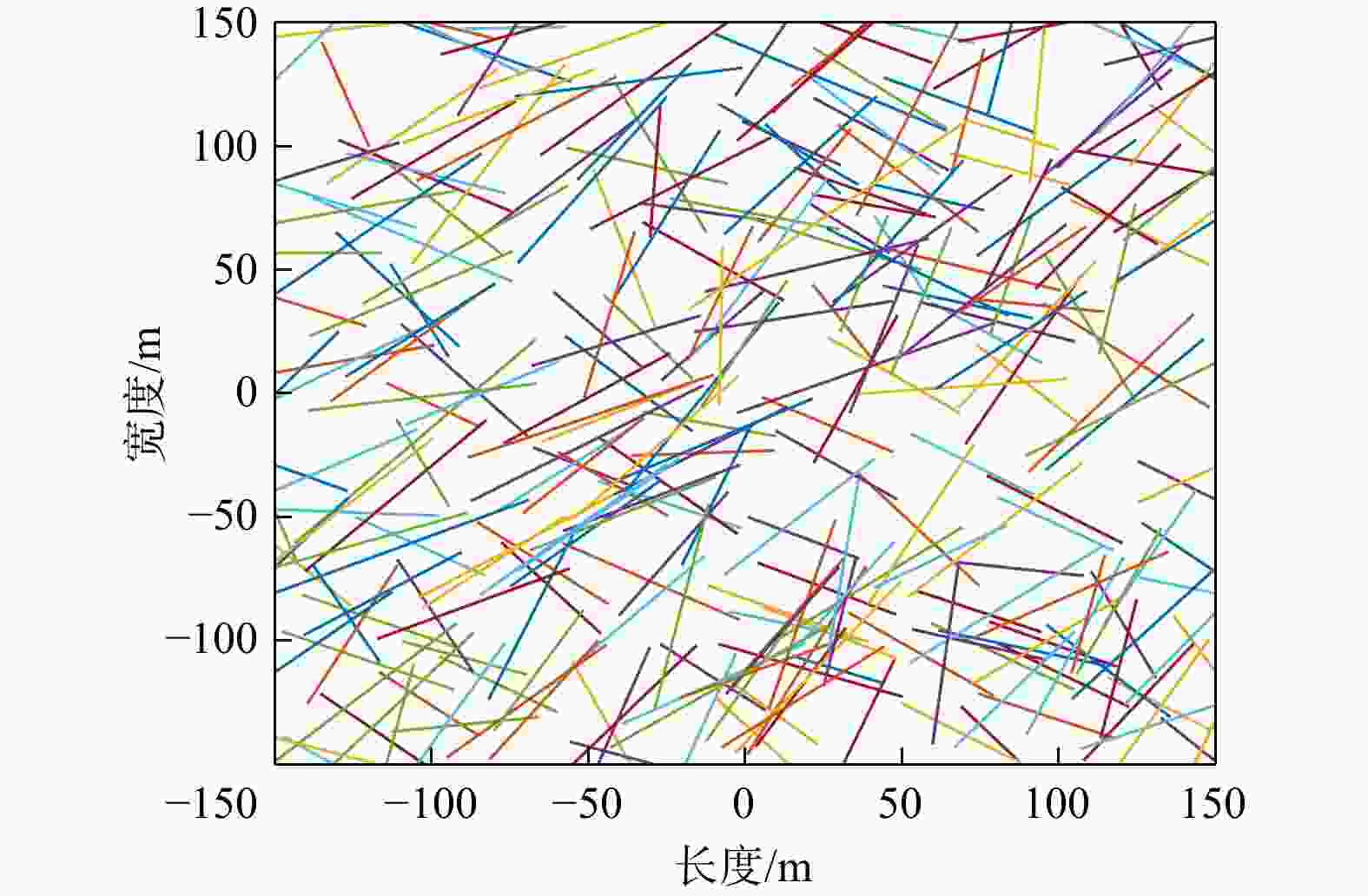

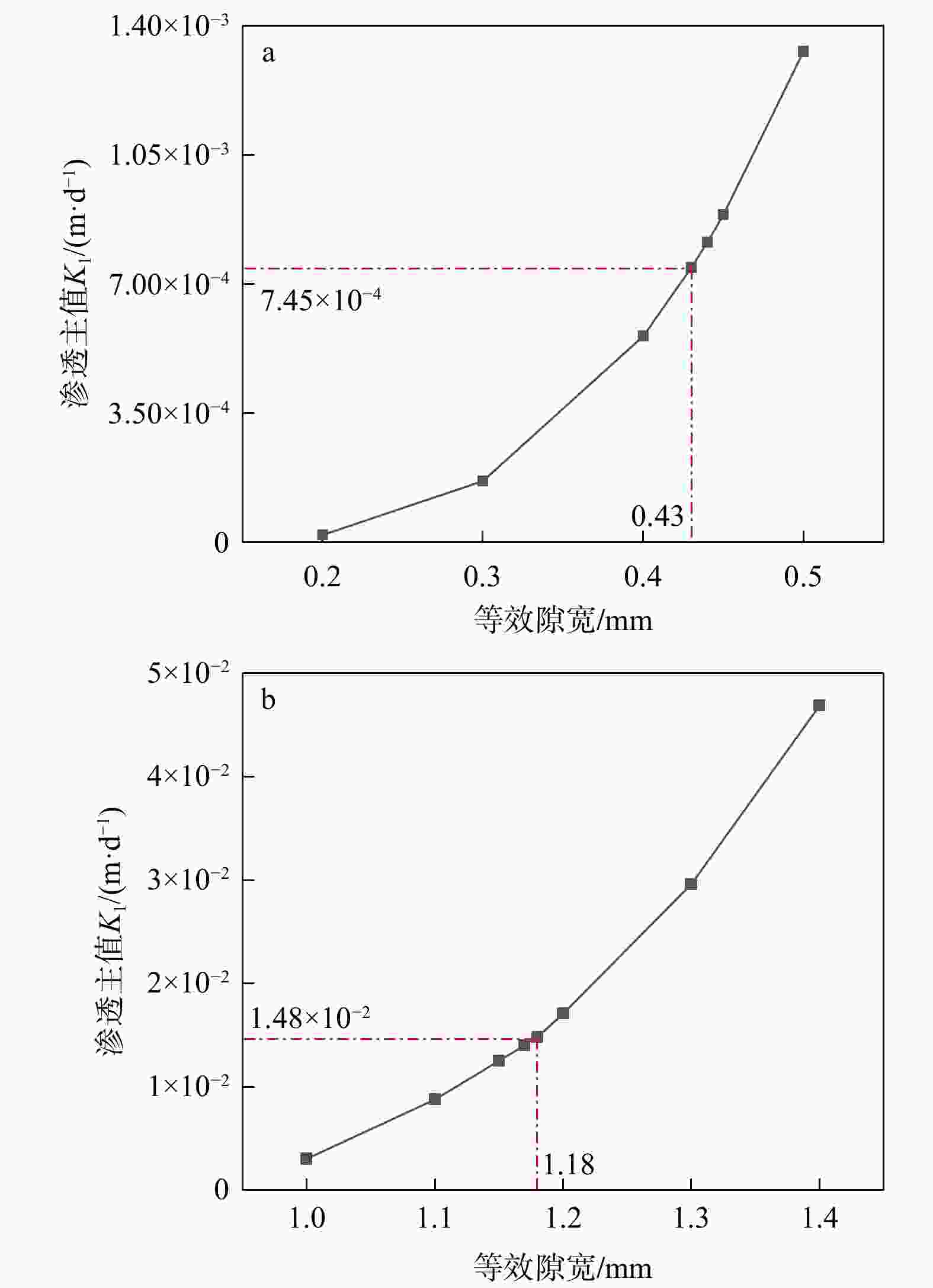

Methods In this paper, aimed at addressing this problem, the geological conditions and fracture distribution characteristics of the reservoir site area are analyzed based on a large underground cavern expansion project. Considering the joint dense zone connecting the two-stage caverns, and based on the field hydrological test results, the equivalent opening of the fracture is inverted. A simplified model of the two-stage underground caverns is then established using the random fracture network (DFN) approach. The water seal safety of the expanded underground caverns is studied, along with the influence of the expanded caverns on the water seal safety of the operating caverns.

Results The research shows that the expanded caverns have no effect on the water seal safety of the operating caverns, but the joint dense zone will seriously affect the water seal safety of the expanded caverns. Through the study of the influence factors of the expansion of the oil depot on the water seal safety of the adjacent operating oil depot, it is determined that the minimum safety distance between the caverns is 200 m, and the vertical and horizontal water curtain pressures are set to 0.4 MPa. These settings can guarantee the water seal safety of both the expanded and operating caverns.

Conclusion Therefore, for large-scale underground cavern expansion projects, the joint dense zone is the key factor affecting water seal safety. Ensuring a minimum safety distance and appropriate water curtain pressure can effectively ensure the safety of both the expanded and operating caverns. The results provide a theoretical basis for studying water seal safety in the expansion of large underground caverns.

-

Key words:

- DFN /

- underground caverns /

- cavern enlargement /

- water-sealed properties /

- safe distance

-

表 1 各组节理统计频数分布

Table 1. Statistical frequency distribution of each group of joints

参数名 节理1 节理2 节理3 节理4 倾向/(°) 范围 SW200°~SW290° SE100°~SW190° SE230°~SW280° SE230°~SW280° 期望μ 238 140 252 126 标准差δ 17.6 20.5 12.2 14.6 倾角/(°) 范围 50~90 50~90 50~90 50~90 期望μ 71 68 72 65 标准差δ 8.3 8.1 9.21 6.2 迹长/m 范围 55~70 55~70 55~70 55~70 期望μ 55 70 55 70 标准差δ 9.37 12.16 9.37 11.25 线密度(条/m) 0.05 0.06 0.19 0.14 表 2 岩石物理力学参数和裂隙参数

Table 2. Rock Physical and Mechanical Parameters

岩石物理力学参数 取值 裂隙参数 取值 密度/(kg/m3) 2620 法向刚度/(GPa/m) 0.95 体积模量/GPa 21 切向刚度/(GPa/m) 0.7 剪切模量/GPa 10.81 抗拉强度/MPa 2.52 抗压强度/MPa 91.84 粘聚力/MPa 0.13 抗拉强度/MPa 5.63 摩擦角/(°) 45.7 粘聚力/MPa 16.33 摩擦角/(°) 57.85 表 3 各组节理等效开度取值

Table 3. Value table of equivalent opening of joints in each group

节理编号 水力开度/mm 最大节理时 最小节理时 法向应力为0时 J1 3 0.01 0.43 J2 3 0.01 0.43 J3 3 0.01 1.18 J4 3 0.01 1.18 -

[1] 柴军瑞, 仵彦卿. 岩体多重裂隙网络渗流模型研究[J]. 煤田地质与勘探, 2000, 28(2): 33-36.CHAI J R, WU Y Q. On seepage model for rock mass of multi-level fracture network[J]. Coal Geology & Exploration, 2000, 28(2): 33-36. (in Chinese with English abstract [2] 王者超, 张彬, 乔丽苹, 等. 中国地下水封储存理论与关键技术研究进展[J]. 油气储运, 2022, 41(9): 995-1003. doi: 10.6047/j.issn.1000-8241.2022.09.001WANG Z C, ZHANG B, QIAO L P, et al. Research progress on theories and key technologies of underground water-sealed storage in China[J]. Oil & Gas Storage and Transportation, 2022, 41(9): 995-1003. (in Chinese with English abstract doi: 10.6047/j.issn.1000-8241.2022.09.001 [3] 张彬, 石磊, 杨森, 等. 新建地下水封油库对附近运行油库水封可靠性影响研究[J]. 工程地质学报, 2016, 24(5): 815-822. doi: 10.13544/j.cnki.jeg.2016.05.011ZHANG B, SHI L, YANG S, et al. Minimum separation distance between existing and newly constructing underground water-sealed oil storages[J]. Journal of Engineering Geology, 2016, 24(5): 815-822. (in Chinese with English abstract doi: 10.13544/j.cnki.jeg.2016.05.011 [4] 冯树荣, 蒋中明, 张金龙, 等. 地下水封石油洞库水封准则研究[J]. 岩土工程学报, 2014, 36(5): 886-891. doi: 10.11779/CJGE201405011FENG S R, JIANG Z M, ZHANG J L, et al. Water sealing criteria for underground oil storage in unlined rock caverns[J]. Chinese Journal of Geotechnical Engineering, 2014, 36(5): 886-891. (in Chinese with English abstract doi: 10.11779/CJGE201405011 [5] ÅBERG B. Prevention of gas leakage from unlined reservoirs in rock[M]. Amsterdam: Elsevier, 1978: 399-413. [6] GOODALL D C, ÅBERG B, BREKKE T L. Fundamentals of gas containment in unlined rock caverns[J]. Rock Mechanics and Rock Engineering, 1988, 21(4): 235-258. doi: 10.1007/BF01020278 [7] SUH J K, CHUNG H S, KIM C W. Study on the condition of preventing gas leakage from the unlined rock cavern[C]//Anon. Proceedings of the International Symposium on Large Rock Caverns. [S. 1. ]: [s. n. ], 1986: 725-736. [8] 王者超, 李术才, 乔丽苹, 等. 大型地下石油洞库自然水封性应力–渗流耦合分析[J]. 岩土工程学报, 2013, 35(8): 1535-1543.WANG Z C, LI S C, QIAO L P, et al. Assessment of natural containment properties of an underground crude oil storage cavern using fluid flow-stress coupling method[J]. Chinese Journal of Geotechnical Engineering, 2013, 35(8): 1535-1543. (in Chinese with English abstract [9] 张振刚, 谭忠盛, 万姜林, 等. 水封式LPG地下储库渗流场三维分析[J]. 岩土工程学报, 2003, 25(3): 331-335.ZHANG Z G, TAN Z S, WAN J L, et al. Three-dimensional seepage analysis of underground LPG storage with water curtain[J]. Chinese Journal of Geotechnical Engineering, 2003, 25(3): 331-335. (in Chinese with English abstract [10] 谭忠盛, 万姜林, 张振刚. 地下水封式液化石油气储藏洞库修建技术[J]. 土木工程学报, 2006, 39(6): 88-93. doi: 10.3321/j.issn:1000-131X.2006.06.016TAN Z S, WAN J L, ZHANG Z G. Construction technology of underground water-seal liquefied petroleum gas storage[J]. China Civil Engineering Journal, 2006, 39(6): 88-93. (in Chinese with English abstract doi: 10.3321/j.issn:1000-131X.2006.06.016 [11] 李术才, 平洋, 王者超, 等. 基于离散介质流固耦合理论的地下石油洞库水封性和稳定性评价[J]. 岩石力学与工程学报, 2012, 31(11): 2161-2170.LI S C, PING Y, WANG Z C, et al. Assessments of containment and stability of underground crude oil storage caverns based on fluid-solid coupling theory for discrete medium[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(11): 2161-2170. (in Chinese with English abstract [12] 王者超, 李术才, 梁建毅, 等. 地下水封石油洞库渗水量预测与统计[J]. 岩土工程学报, 2014, 36(8): 1490-1497. doi: 10.11779/CJGE201408015WANG Z C, LI S C, LIANG J Y, et al. Prediction and measurement of groundwater flow rate of underground crude oil storage caverns[J]. Chinese Journal of Geotechnical Engineering, 2014, 36(8): 1490-1497. (in Chinese with English abstract doi: 10.11779/CJGE201408015 [13] 荆少东, 许国辉, 吴尚彬, 等. 基于三维精细化数值模型的地下油库水封安全评价[J]. 地质科技通报, 2023, 42(6): 1-11. doi: 10.19509/j.cnki.dzkq.tb20220097JING S D, XU G H, WU S B, et al. Assessment of the water-sealed safety of underground crude oil storage based on a three-dimensional refined numerical model[J]. Bulletin of Geological Science and Technology, 2023, 42(6): 1-11. (in Chinese with English abstract doi: 10.19509/j.cnki.dzkq.tb20220097 [14] SHI L, ZHANG B, WANG L, et al. Functional efficiency assessment of the water curtain system in an underground water-sealed oil storage cavern based on time-series monitoring data[J]. Engineering Geology, 2018, 239: 79-95. doi: 10.1016/j.enggeo.2018.03.015 [15] 彭振华, 乔丽苹, 黄安达, 等. 基于地下水化学特征的水封油库水幕系统有效性评价[J]. 水文地质工程地质, 2024, 51(3): 34-42. doi: 10.16030/j.cnki.issn.1000-3665.202305049PENG Z H, QIAO L P, HUANG A D, et al. Evaluation of water curtain system effectiveness for underground crude oil storage caverns based on hydrogeochemical characteristics[J]. Hydrogeology & Engineering Geology, 2024, 51(3): 34-42. (in Chinese with English abstract doi: 10.16030/j.cnki.issn.1000-3665.202305049 [16] 刘乾灵, 张彬, 李玉涛, 等. MICP技术在地下水封油库渗控注浆中的应用潜力[J]. 工程地质学报, 2024, 32(4): 1412-1423. doi: 10.13544/j.cnki.jeg.2021-0824LIU Q L, ZHANG B, LI Y T, et al. Application potential of micp in seepage control grouting of underground water-sealed oil storage cavern[J]. Journal of Engineering Geology, 2024, 32(4): 1412-1423. (in Chinese with English abstract doi: 10.13544/j.cnki.jeg.2021-0824 [17] 蒋中明, 肖喆臻, 唐栋, 等. 基于裂隙渗流效应的水封油库涌水量预测分析[J]. 岩土力学, 2022, 43(4): 1041-1047. doi: 10.16285/j.rsm.2021.1217JIANG Z M, XIAO Z Z, TANG D, et al. Prediction of water inflow in water-sealed oil storage caverns based on fracture seepage effect[J]. Rock and Soil Mechanics, 2022, 43(4): 1041-1047. (in Chinese with English abstract doi: 10.16285/j.rsm.2021.1217 [18] ZHANG B, SHI L, YU X, et al. Assessing the water-sealed safety of an operating underground crude oil storage adjacent to a new similar cavern: A case study in China[J]. Engineering Geology, 2019, 249: 257-272. doi: 10.1016/j.enggeo.2019.01.008 [19] 李玉涛, 张彬, 石磊, 等. 垂直水幕作用下扩建地下水封油库布局方式研究[J]. 隧道建设(中英文), 2019, 39(8): 1308-1318. doi: 10.3973/j.issn.2096-4498.2019.08.012LI Y T, ZHANG B, SHI L, et al. Enlargement layout of underground water-sealed oil storage cavern with vertical water curtain system[J]. Tunnel Construction, 2019, 39(8): 1308-1318. (in Chinese with English abstract doi: 10.3973/j.issn.2096-4498.2019.08.012 [20] 张彬, 李玉涛, 石磊, 等. 海岛环境下地下水封油库海水入侵数值模拟研究[J]. 工程地质学报, 2018, 26(5): 1366-1374.ZHANG B, LI Y T, SHI L, et al. Numerical simulation of seawater intrusion in underground oil storage cavern in island environment[J]. Journal of Engineering Geology, 2018, 26(5): 1366-1374. (in Chinese with English abstract [21] 彭振华, 张彬, 李玉涛, 等. 海岛地下水封洞库围岩稳定性及水封可靠性研究[J]. 地下空间与工程学报, 2020, 16(6): 1875-1881.PENG Z H, ZHANG B, LI Y T, et al. Study on surrounding rock stability and water-sealed reliability of underground crude oil storage cavern in island[J]. Chinese Journal of Underground Space and Engineering, 2020, 16(6): 1875-1881. (in Chinese with English abstract [22] 孙哲, 张彬, 陈大伟, 等. 花岗岩裂隙岩体油水两相渗流可视化试验及数值模拟研究[J]. 地学前缘, 2023, 30(3): 465-475. doi: 10.13745/j.esf.sf.2022.12.54SUN Z, ZHANG B, CHEN D W, et al. Two-phase oil/water seepage in fractured granite rock mass: Insight from seepage visualization experiment and numerical simulation[J]. Earth Science Frontiers, 2023, 30(3): 465-475. (in Chinese with English abstract doi: 10.13745/j.esf.sf.2022.12.54 [23] YU C, DENG S C, LI H B, et al. The anisotropic seepage analysis of water-sealed underground oil storage caverns[J]. Tunnelling and Underground Space Technology, 2013, 38: 26-37. doi: 10.1016/j.tust.2013.05.003 [24] 李术才, 张立, 马秀媛, 等. 大型地下水封石油洞库渗流场时空演化特征研究[J]. 岩土力学, 2013, 34(7): 1979-1986.LI S C, ZHANG L, MA X Y, et al. Space-time evolution behaviour of seepage field around a large underground petroleum storage caverns with groundwater curtaining[J]. Rock and Soil Mechanics, 2013, 34(7): 1979-1986. (in Chinese with English abstract [25] WANG Z C, LI S C, QIAO L P. Design and test aspects of a water curtain system for underground oil storage caverns in China[J]. Tunnelling and Underground Space Technology, 2015, 48: 20-34. doi: 10.1016/j.tust.2015.01.009 [26] 张奇华, 李玉婕, 袁东, 等. 地下水封洞库水幕孔注水试验及岩体等效渗透参数分析[J]. 岩土力学, 2015, 36(9): 2648-2658. doi: 10.16285/j.rsm.2015.09.027ZHANG Q H, LI Y J, YUAN D, et al. Water injection test about water curtain borehole for underground water-sealed cavern and analysis of rock equivalent permeability parameter[J]. Rock and Soil Mechanics, 2015, 36(9): 2648-2658. (in Chinese with English abstract doi: 10.16285/j.rsm.2015.09.027 [27] 吴越. 地下水封油库围岩优势渗流通道辨识方法及应用[D]. 北京: 中国地质大学(北京), 2018.WU Y. The identification method and application of advantage seepage channel in surrounding rock of underground oil storage caverns[D]. Beijing: China University of Geosciences(Beijing), 2018. (in Chinese with English abstract [28] 程锦波, 夏露, 于青春. 基于三维裂隙网络模拟和单孔压水试验的裂隙张开度确定方法[J]. 地质科技通报, 2024, 43(4): 262-272. doi: 10.19509/j.cnki.dzkq.tb20230128CHENG J B, XIA L, YU Q C. Determination method of fracture aperture based on three-dimensional fracture network simulation and water injection tests[J]. Bulletin of Geological Science and Technology, 2024, 43(4): 262-272. (in Chinese with English abstract doi: 10.19509/j.cnki.dzkq.tb20230128 [29] 董晓飞, 胡成, 曹孟雄, 等. 裂隙介质渗透性的升尺度转换研究[J]. 地质科技通报, 2023, 42(4): 259-267. doi: 10.19509/j.cnki.dzkq.tb20230023DONG X F, HU C, CAO M X, et al. Study on the upscaling transformation of hydraulic conductivity in fractured media[J]. Bulletin of Geological Science and Technology, 2023, 42(4): 259-267. (in Chinese with English abstract doi: 10.19509/j.cnki.dzkq.tb20230023 [30] 李露露, 李牧阳, 周志超, 等. 基于统计均质区方法的裂隙几何及渗流特性评价[J]. 地质科技通报, 2023, 42(4): 288-298.LI L L, LI M Y, ZHOU Z C, et al. Assessment of fractures geometries and seepage characteristics based on statistical homogeneous zone method[J]. Bulletin of Geological Science and Technology, 2023, 42(4): 288-298. (in Chinese with English abstract [31] SNOW D T. A parallel plate model of fractured permeable media[D]. San Francisco: University of California, Berkeley, 1965. [32] BEAR J. Dynamics of fluids in porous media[M]. NEW YORK: Elsevier, 1972. [33] BAGHBANAN A, JING L R. Hydraulic properties of fractured rock masses with correlated fracture length and aperture[J]. International Journal of Rock Mechanics and Mining Sciences, 2007, 44(5): 704-719. doi: 10.1016/j.ijrmms.2006.11.001 [34] 冯军伟. 地下水封油库裂隙围岩渗流等效性研究[D]. 北京: 中国地质大学(北京), 2018.FENG J W. Study on the seepage equivalent of fractures surrounding rock in underground water seal reservoir[D]. Beijing: China University of Geosciences, 2018. (in Chinese with English abstract [35] 刘海军. 基于蒙特卡罗法的岩体裂隙网络模型及渗透张量的研究[D]. 哈尔滨: 哈尔滨工业大学, 2011.LIU H J. Studies on discrete fracture network modeling based on Monte-Carlo and permeability tensor of rock masses[D]. Harbin: Harbin Institute of Technology, 2011. (in Chinese with English abstract [36] 陈剑平. 岩体随机不连续面三维网络数值模拟技术[J]. 岩土工程学报, 2001, 23(4): 397-402.CHEN J P. 3-D net work numerical modeling technique for random discontinuities of rock mass[J]. Chinese Journal of Geotechnical Engineering, 2001, 23(4): 397-402. (in Chinese with English abstract [37] 贾洪彪, 马淑芝, 唐辉明, 等. 岩体结构面网络三维模拟的工程应用研究[J]. 岩石力学与工程学报, 2002, 21(7): 976-979. doi: 10.3321/j.issn:1000-6915.2002.07.008JIA H B, MA S Z, TANG H M, et al. Study on engineering application of 3-D modeling of rock discontinuity network[J]. Chinese Journal of Rock Mechanics and Engineering, 2002, 21(7): 976-979. (in Chinese with English abstract doi: 10.3321/j.issn:1000-6915.2002.07.008 [38] 张超. 大型地下水封油库水幕系统作用机理与优化研究[D]. 北京: 中国地质大学(北京), 2016.ZHANG C. Study of mechanism and optimization setting about large underground water oil storage’s water curtain system[D]. Beijing: China University of Geosciences, 2016. (in Chinese with English abstract -

下载:

下载: