-

摘要:

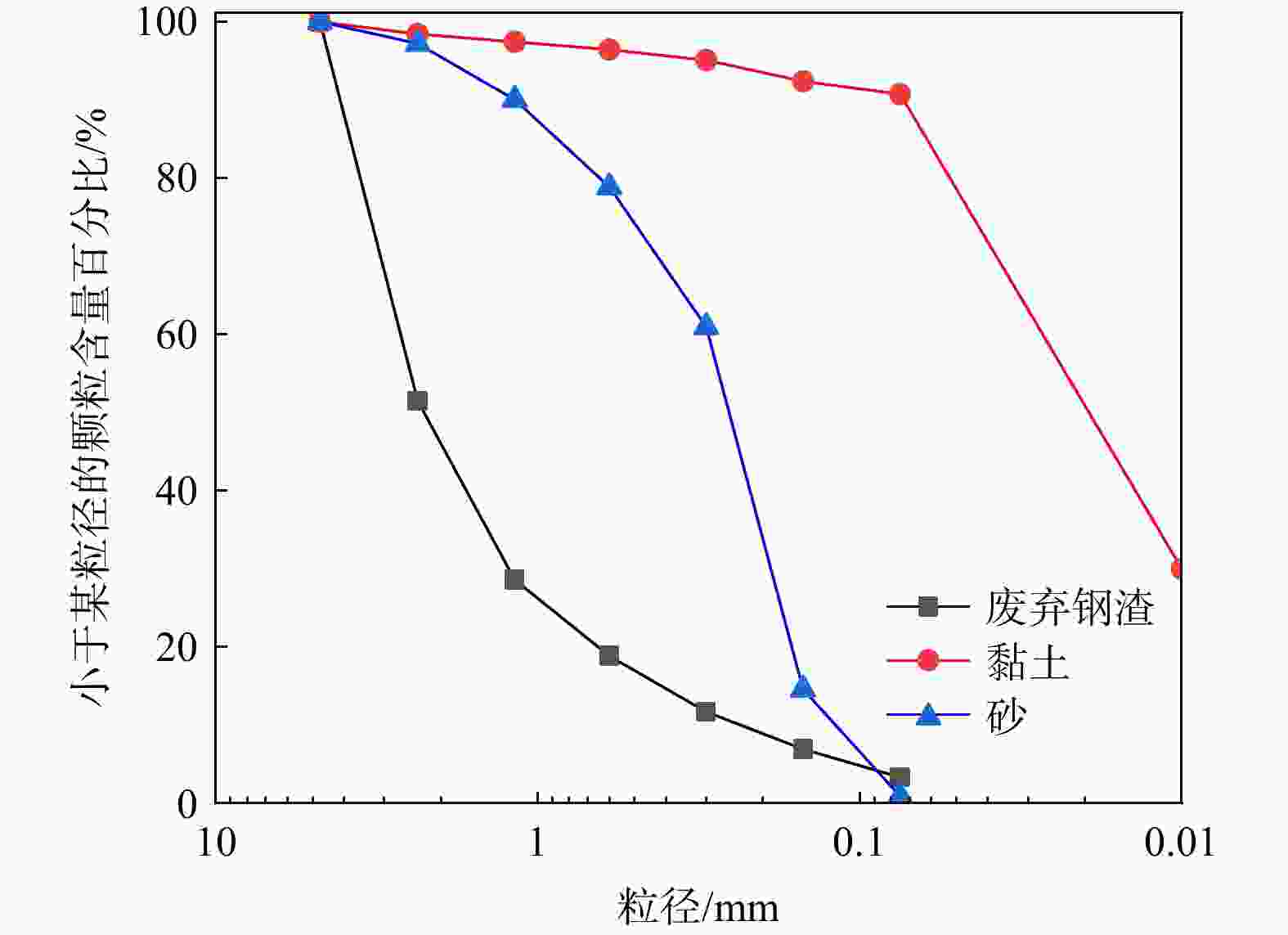

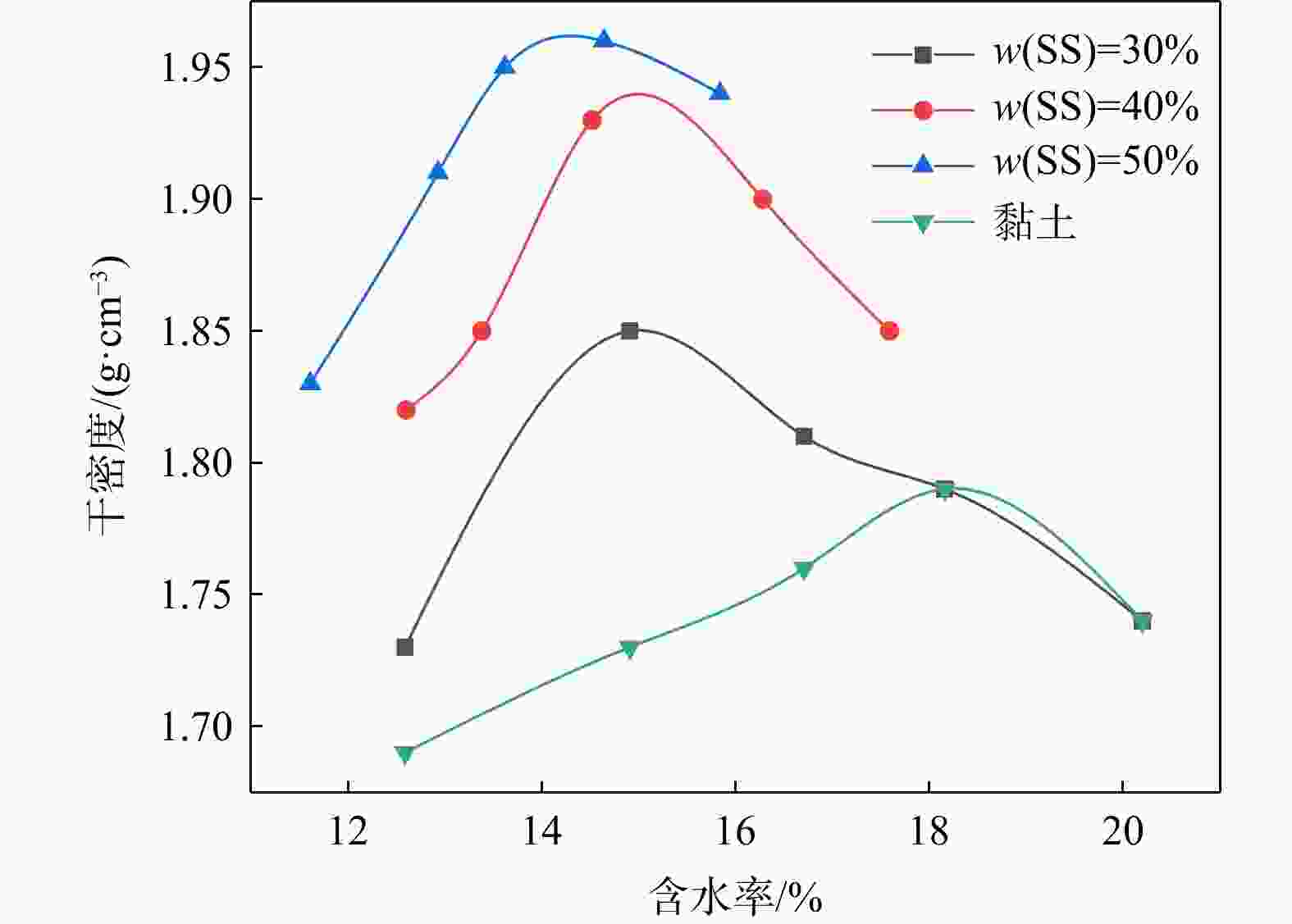

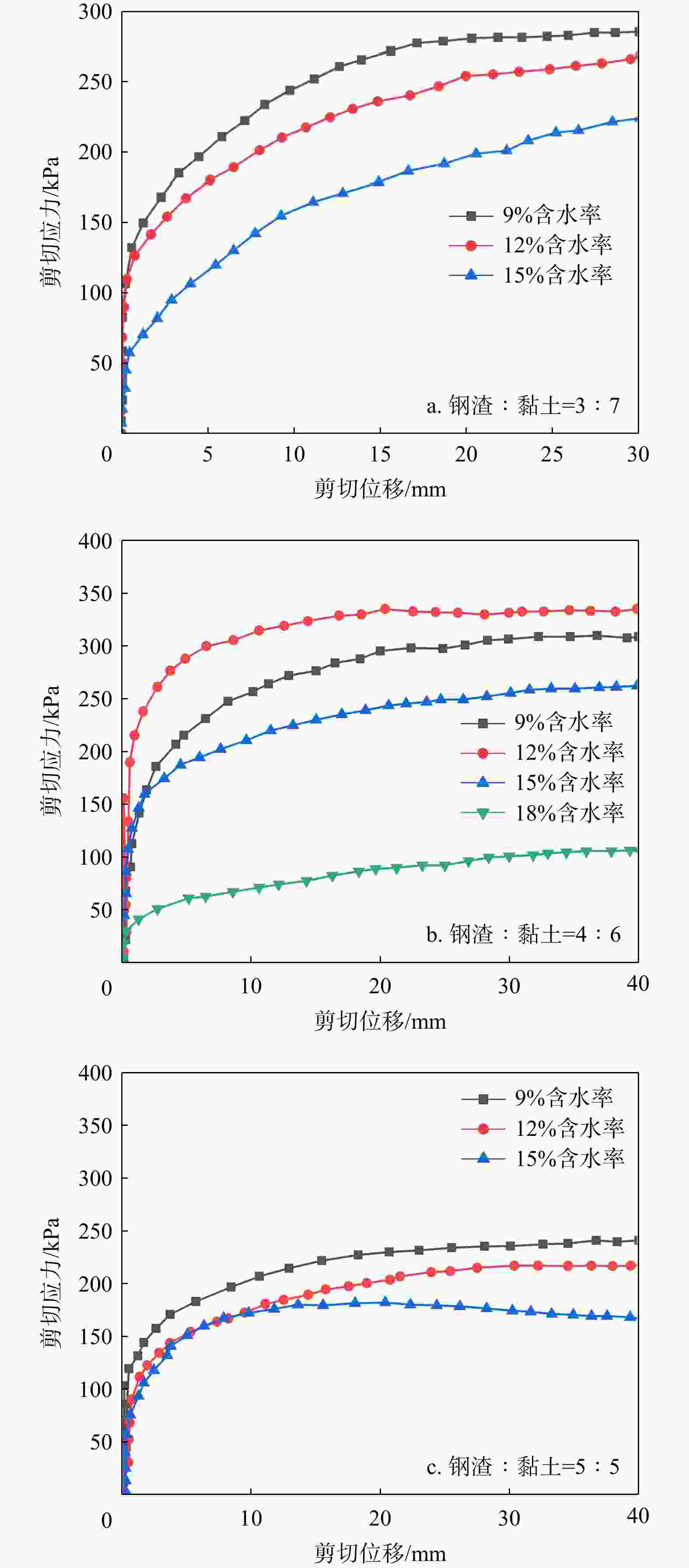

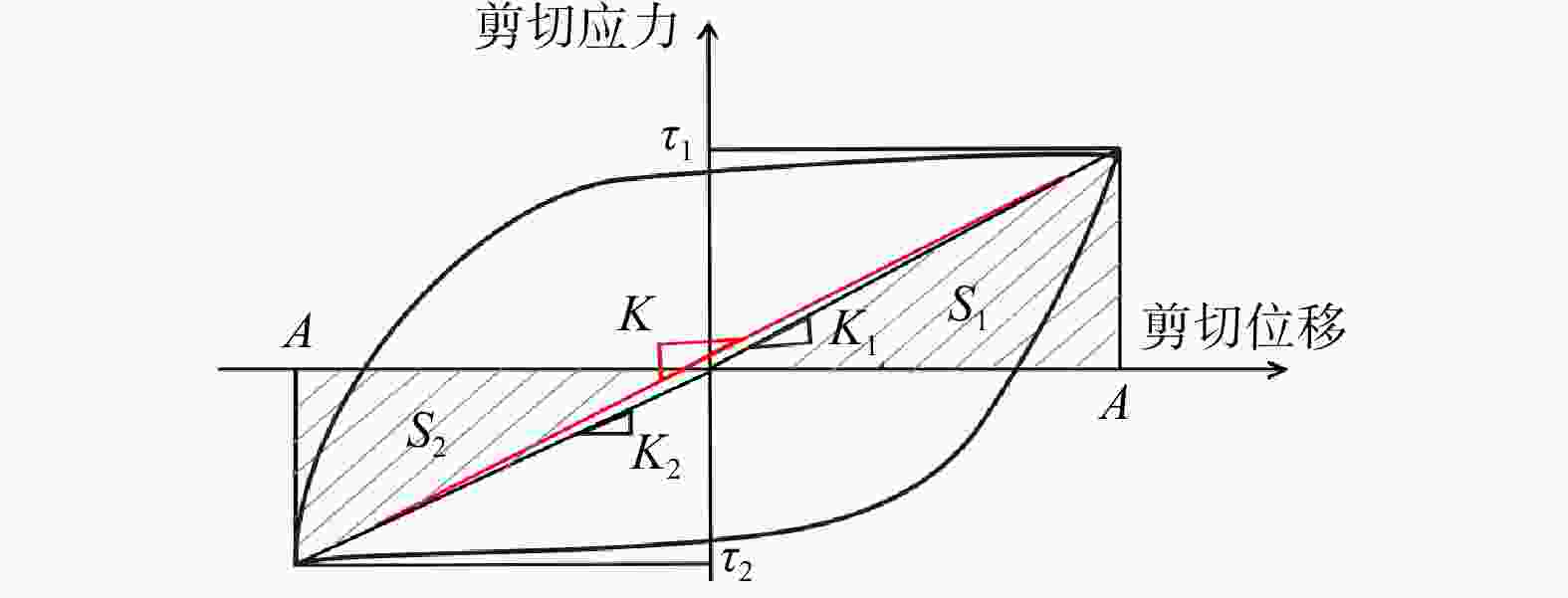

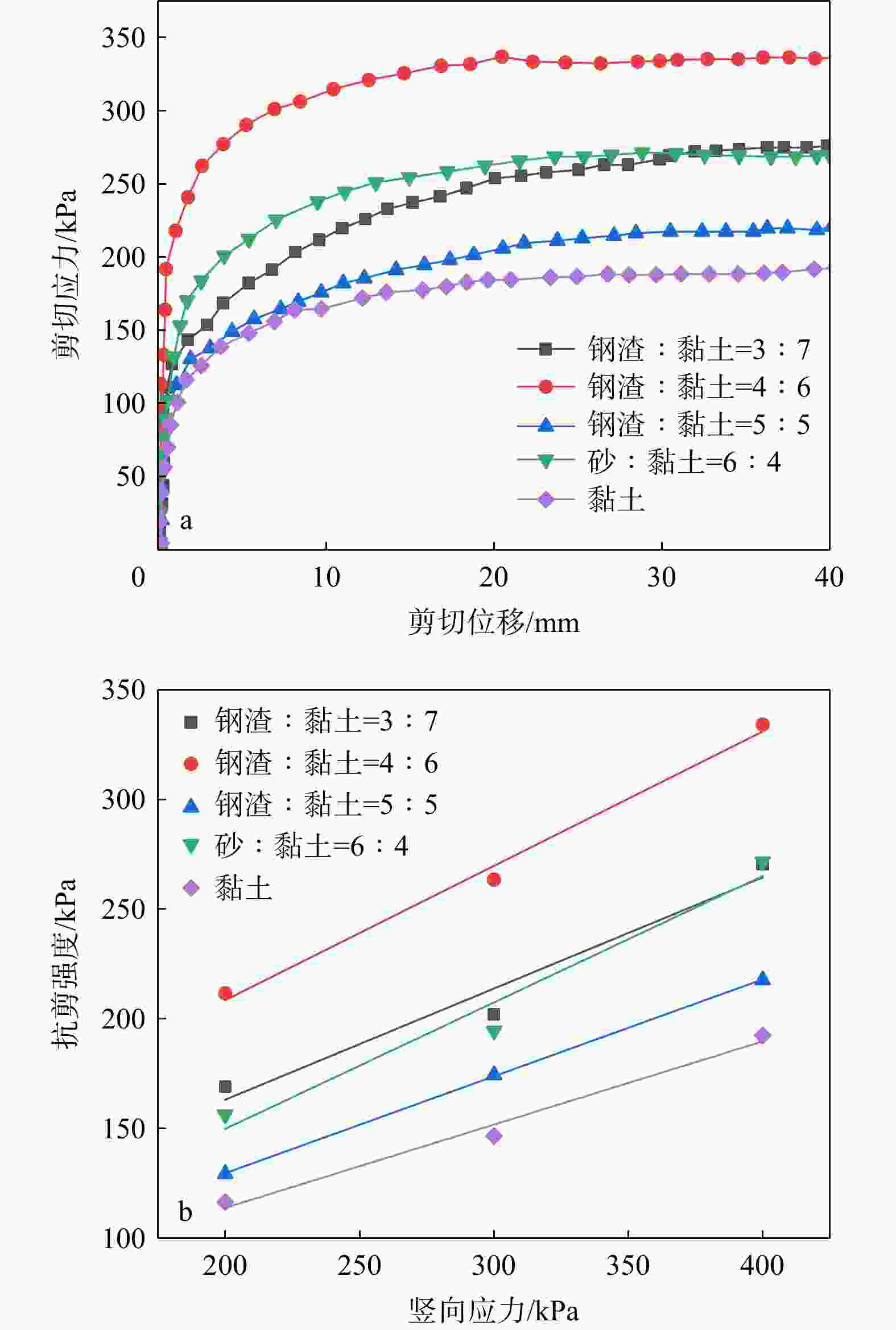

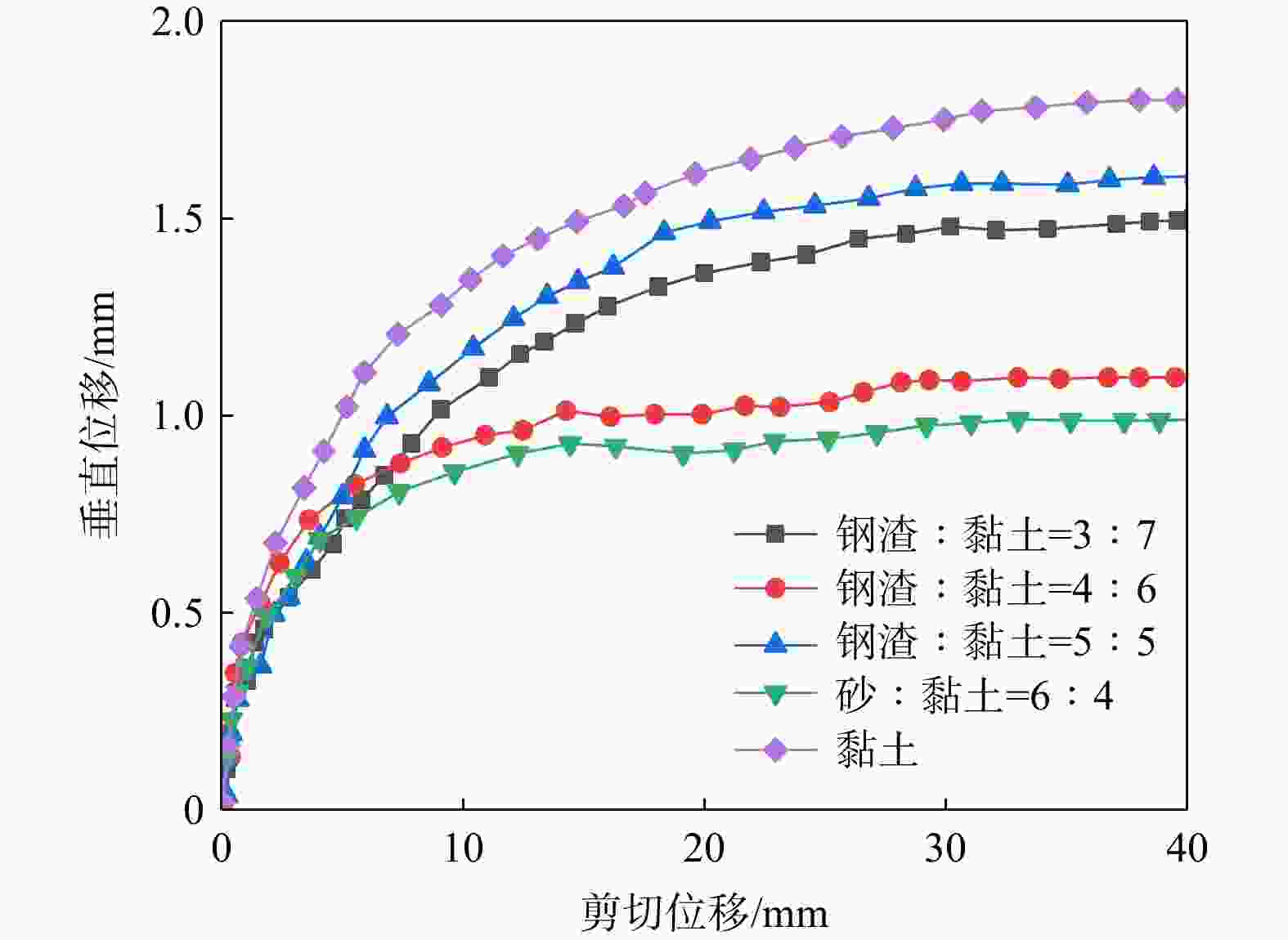

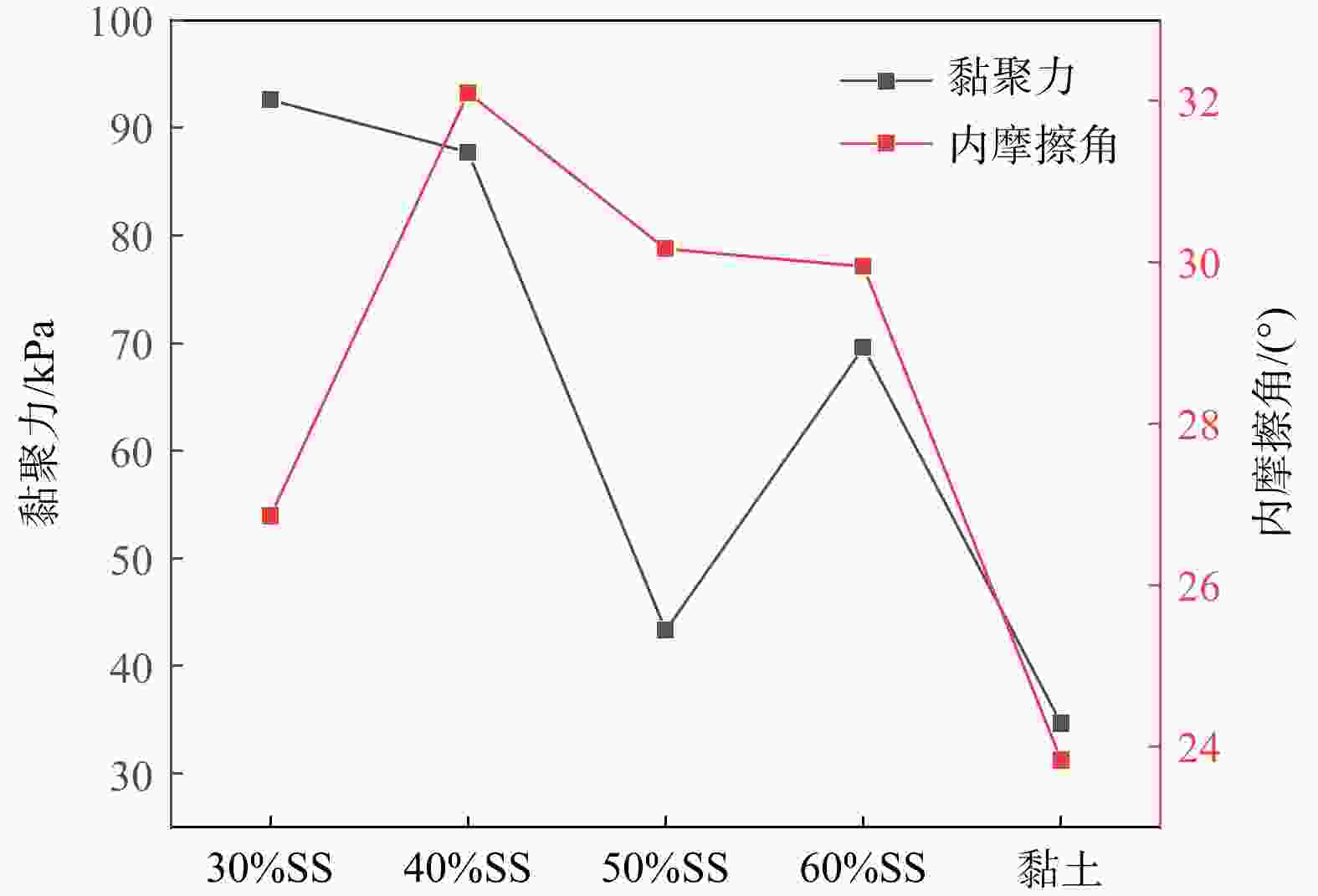

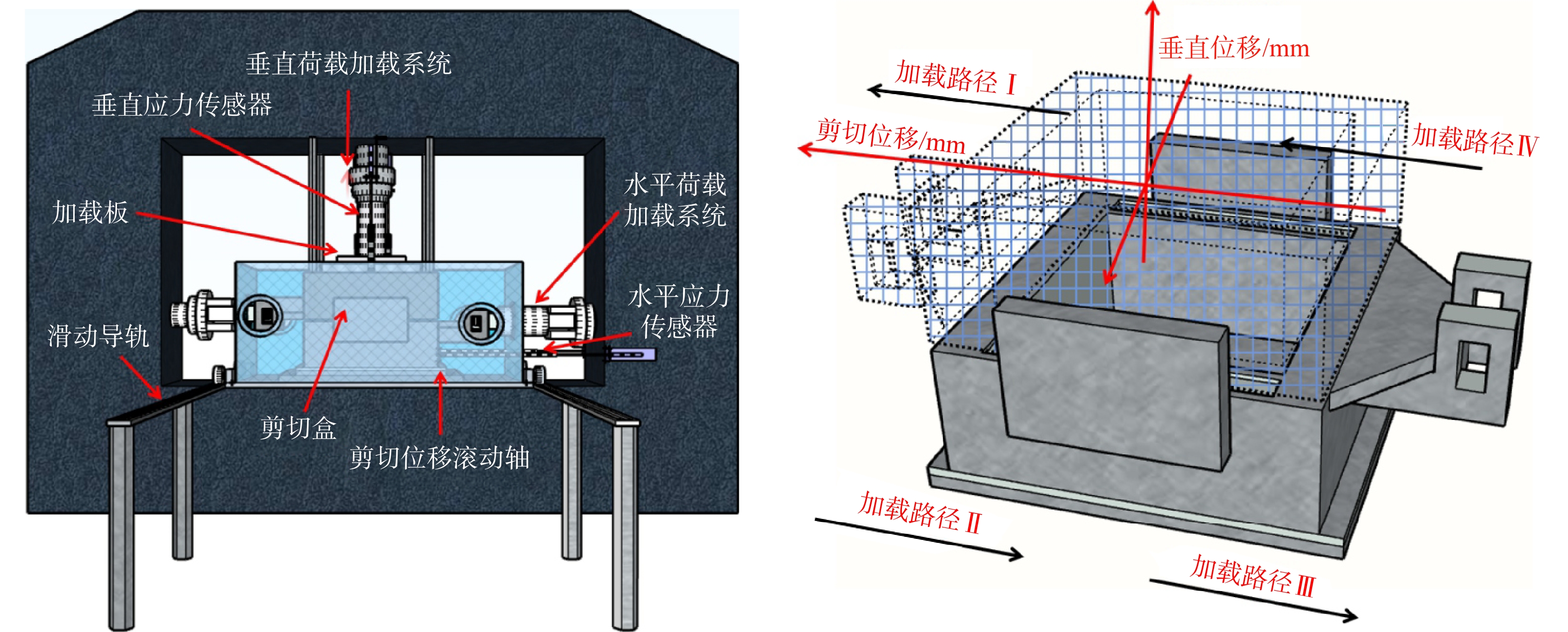

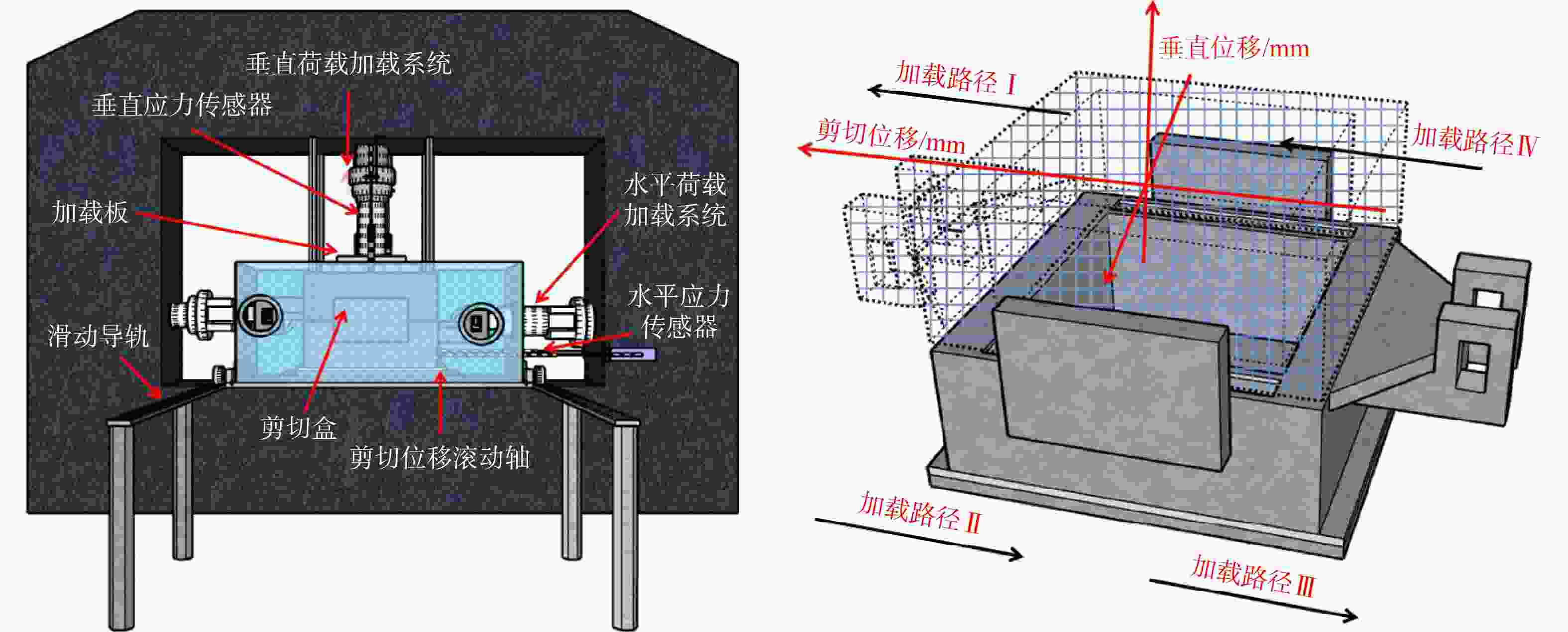

为改善黏土工程特性和增加废弃钢渣(SS)利用率,铺设土工格栅加筋,然后对钢渣−黏土混合土、砂−黏土混合土及黏土分别进行了直剪试验、循环剪切试验和循环后直剪试验,研究了不同钢渣掺量、竖向应力、含水率、剪切幅值条件下,混合土筋−土界面强度特征、阻尼比、剪切刚度变化和混合土体位移情况。试验结果表明:钢渣可以显著提高黏土筋−土界面抗剪强度,且改良效果优于常规材料砂改良黏土;钢渣−黏土混合土具有较大阻尼比和剪切刚度,说明其具有较好的减震耗能性。其中,40%钢渣掺量下的钢渣−黏土混合土抗剪强度、阻尼比和剪切刚度较优;相较于循环前直剪,经过循环荷载作用后钢渣−黏土混合土抗剪强度有所提升。此外,与竖向应力和剪切幅值相比,含水率对钢渣−黏土混合土的抗剪强度、剪切刚度和阻尼比有较大影响。钢渣−黏土混合土在循环剪切荷载作用下,可以呈现更好的减震耗能性,试验结果可为钢渣代替砂改良黏土提供理论依据。

Abstract:Objective To improve the engineering properties of clay and increase the utilization of waste steel slag (SS).

Methods Geogrid reinforcement was employed, followed by direct shear tests, cyclic shear tests, and post-cyclic direct shear tests conducted on steel slag-clay mix, sand-clay mix, and pure clay. The study investigated the strength characteristics, damping ratio, shear stiffness changes, and displacement of the mixed soil reinforcement-soil interface under various conditions, including different steel slag contents, vertical stress, moisture content, and shear amplitudes.

Results The test results indicate that steel slag significantly enhances the shear strength of the clay-reinforcement interface, with improvement being more effective than conventional sand-modified clay. The steel slag-clay mixed soil exhibited higher damping ratio and shear stiffness, suggesting better vibration damping and energy dissipation properties. Among the various mixtures, the steel slag-clay mix with 40% steel slag content demonstrated the best shear strength, damping ratio, and shear stiffness. Additionally, the shear strength of the steel slag-clay mixed soil increased after cyclic loading compared to pre-cyclic direct shear conditions. The results also show that moisture content has a more significant impact on shear strength, shear stiffness, and damping ratio than vertical stress and shear amplitude.

Conclusion The steel slag-clay mixed soil exhibits improved damping and energy dissipation properties under cyclic shear loading. The experimental findings provide a theoretical basis for using steel slag as a substitute for sand to improve clay soils.

-

Key words:

- steel slag-clay mix /

- direct shear /

- cyclic shear /

- shear stiffness /

- damping ratio

-

表 1 试验材料基本物理指标

Table 1. Basic physical property index of materials in tests

类型 最大干密

度/(g·cm-3)天然含水

率/%曲率

系数不均匀

系数塑限/% 液限/% 塑性

指数黏土 1.79 6.3 2.81 7.59 24.9 50.9 26 砂 1.83 6.5 0.5 2.2 - - - 钢渣 2.4 8.1 2.3 11.3 - - - 表 2 钢渣化学成分组成

Table 2. Chemical composition of steel slag

wB/% 成分 MgO Al2O3 SiO2 CaO Fe2O3 TiO2 MnO 其他 钢渣(SS) 12.9 8.7 26.5 34.0 12.9 0.6 1.2 3.1 表 3 土工格栅技术指标

Table 3. Technical index of geogrid

材料 厚度/

mm单位面积质量/

(g·m−2)网孔尺寸

长×宽/mm

×mm极限延伸率/

%极限抗拉强度/

(kN·m−1)横向 纵向 横向 纵向 聚丙烯 2 250 35×25 13.2 15.6 20 表 4 试验方案

Table 4. Experiment scheme

试验类型 试验

编号试样 竖向应

力/kPa剪切幅

值/mm含水率/% 压实度/% 直剪试验 T-1 30%SS+70%C 200/300/400 - 9/12/15 95 T-2 40%SS+60%C 200/300/400 - 9/12/15 95 T-3 50%SS+50%C 200/300/400 - 9/12/15 95 T-4 60%S+40%C 200/300/400 - 16.5 95 T-5 C 200/300/400 - 18 95 循环剪

切试验T-6 30%SS+70%C 400 5 9/12/15 95 T-7 50%SS+50%C 400 5 9/12/15 95 T-8 40%SS+60%C 200/300/400 3/4/5 9/12/15 95 T-9 60%S+40%C 400 5 16.5 95 T-10 C 400 5 18 95 循环后直

剪试验T-11 40%SS+60%C 200/300/400 - 12 95 注: SS. 钢渣;C. 黏土;S. 砂;循环次数均为10次;剪切速率为1 mm/min 表 5 不同条件下黏聚力与内摩擦角对比

Table 5. Comparison of cohesion and internal friction Angle

试样 含水率/% c/kPa φ/(°) 30%SS+70%C 9 117.8 27.9 12 92.6 26.9 15 51.3 24.9 40%SS+60%C 9 108.7 27.3 12 87.7 32.1 15 85.2 25.7 50%SS+50%C 9 67.1 30.2 12 43.3 24.1 15 39.5 19.6 -

[1] KUMAR J, MADHUSUDHAN B N. Dynamic properties of sand from dry to fully saturated states[J]. Géotechnique, 2012, 62(1): 45-54. [2] LI W, LANG L, WANG D, et al. Investigation on the dynamic shear modulus and damping ratio of steel slag sand mixtures[J]. Construction and Building Materials, 2018, 162: 170-180. [3] 李丽华, 文贝, 胡智, 等. 建筑垃圾填料与土工合成材料加筋剪切性能研究[J]. 武汉大学学报(工学版), 2019, 52(4): 311-316.LI L H, WEN B, HU Z, et al. Study on reinforced shear behavior of construction waste filler and geosynthetics[J]. Engineering Journal of Wuhan University, 2019, 52(4): 311-316. (in Chinese with English abstract [4] 李丽华, 肖衡林, 唐辉明, 等. 轮胎颗粒混合土动力特性参数影响规律试验研究[J]. 岩土力学, 2014, 35(2): 359-364.LI L H, XIAO H L, TANG H M, et al. Dynamic properties variation of tire shred-soil mixtures[J]. Rock and Soil Mechanics, 2014, 35(2): 359-364. (in Chinese with English abstract [5] 马鸿发, 刘清秉, 李靖. 掺砂率与干密度对膨润土收缩特性影响[J]. 地质科技通报, 2023, 42(6): 76-85.MA H F, LIU Q B, LI J. Effect of shrinkage characteristics of bentonite with different sand mixing rates and dry densities[J]. Bulletin of Geological Science and Technology, 2023, 42(6): 76-85. (in Chinese with English abstract [6] WANG L Y, ZHANG B, XIE H M, et al. Study on shear strength characteristics of marine silt modified by steel slag[J]. Advances in Civil Engineering, 2021, 2021(1): 9647977. doi: 10.1155/2021/9647977 [7] MAGHOOL F, ARULRAJAH A, SUKSIRIPATTANAPONG C, et al. Geotechnical properties of steel slag aggregates: Shear strength and stiffness[J]. Soils and Foundations, 2019, 59(5): 1591-1601. doi: 10.1016/j.sandf.2019.03.016 [8] WANG L Y, YAN J T, WANG Q, et al. Study on permeability of steel slag and steel alag modifying silt soil as new geo-backfill materials[J]. Advances in Civil Engineering, 2019, 2019(1): 5370748. [9] LIU X W, HU M Y, KE S J, et al. A novel rammed earthen material stabilized with steel slags[J]. Construction and Building Materials, 2018, 189: 1134-1139. doi: 10.1016/j.conbuildmat.2018.09.075 [10] WANG L Y, WANG Q, HUANG X, et al. Experimental investigation on compressive deformation and shear strength characteristics of steel slag in the geotechnical engineering[M]//Anon. Proceedings of GeoShanghai 2018 International Conference: Ground Improvement and Geosynthetics. Singapore: Springer Singapore, 2018: 194-202. [11] 陈爽, 贾凡, 刘斯宏, 等. 错缝堆叠土工袋层间界面的循环剪切特性试验研究[J]. 岩石力学与工程学报, 2021, 40(增刊1): 2945-2953.CHEN S, JIA F, LIU S H, et al. Experiments on the cyclic shear behavior of the interface between staggered stacking soilbags[J]. Chinese Journal of Rock Mechanics and Engineering, 2021, 40(S1): 2945-2953. (in Chinese with English abstract [12] 刘飞禹, 江淮, 王军. 砾石−格栅界面循环剪切软化特性试验研究[J]. 岩土力学, 2021, 42(6): 1485-1492.LIU F Y, JIANG H, WANG J. Experimental study on cyclic shear softening characteristics of gravel-geogrid interface[J]. Rock and Soil Mechanics, 2021, 42(6): 1485-1492. (in Chinese with English abstract [13] 李丽华, 臧天宝, 刘永莉, 等. 纤维底渣混合土循环剪切性能研究[J]. 岩石力学与工程学报, 2021, 40(1): 196-205.LI L H, ZANG T B, LIU Y L, et al. Cyclic shear performance of fiber bottom ash mixed soils[J]. Chinese Journal of Rock Mechanics and Engineering, 2021, 40(1): 196-205. (in Chinese with English abstract [14] 刘飞禹, 童艳光, 汪歆, 等. 筋-土界面刚度软化对加筋土挡墙动力特性的影响[J]. 防灾减灾工程学报, 2021, 41(1): 75-84.LIU F Y, TONG Y G, WANG X, et al. Effect of stiffness softening of reinforcement-soil interface on dynamic characteristics of reinforced retaining wall[J]. Journal of Disaster Prevention and Mitigation Engineering, 2021, 41(1): 75-84. (in Chinese with English abstract [15] 高海军, 董丁明, 赵琪, 等. 循环荷载作用下加筋土路基动力响应研究[J]. 防灾减灾工程学报, 2022, 42(1): 208-215.GAO H J, DONG D M, ZHAO Q, et al. Study on dynamic response of reinforced soil subgrade under cyclic loading[J]. Journal of Disaster Prevention and Mitigation Engineering, 2022, 42(1): 208-215. (in Chinese with English abstract [16] 宋飞, 石磊, 樊明尊. 土工格室加筋正常固结粉质黏土应力应变响应[J]. 地质科技通报, 2024, 43(1): 184-193.SONG F, SHI L, FAN M Z. Stress-strain response of geocell-reinforced normally consolidated silty clay[J]. Bulletin of Geological Science and Technology, 2024, 43(1): 184-193. (in Chinese with English abstract [17] HOLTZ WESLEY G, GIBBS HAROLD J. Triaxial shear tests on pervious gravelly soils[J]. Journal of the Soil Mechanics and Foundations Division, 1956, 82(1): 1-9. [18] DESAI C S, DRUMM E C, ZAMAN M M. Cyclic testing and modeling of interfaces[J]. Journal of Geotechnical Engineering, 1985, 111(6): 793-815. doi: 10.1061/(ASCE)0733-9410(1985)111:6(793) [19] NYE C J, FOX P J. Dynamic shear behavior of a needle-punched geosynthetic clay liner[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2007, 133(8): 973-983. doi: 10.1061/(ASCE)1090-0241(2007)133:8(973) [20] 刘飞禹, 王攀, 王军, 等. 筋—土界面循环剪切刚度和阻尼比的试验研究[J]. 岩土力学, 2016, 37(增刊1): 159-165.LIU F Y, WANG P, WANG J, et al. Experimental research on reinforcement-soil interface stiffness and damping ratio under cyclic shearing[J]. Rock and Soil Mechanics, 2016, 37(S1): 159-165. (in Chinese with English abstract [21] 刘飞禹, 施静, 王军, 等. 三明治形加筋土筋-土界面动力剪切特性[J]. 岩土力学, 2018, 39(6): 1991-1998.LIU F Y, SHI J, WANG J, et al. Dynamic shear behavior of interface for clay reinforced with geogrid encapsulated in thin layers of sand[J]. Rock and Soil Mechanics, 2018, 39(6): 1991-1998. (in Chinese with English abstract [22] 中华人民共和国交通部. 公路工程土工合成材料试验规程: JTGE 50−2006[S]. 北京: 人民交通出版社, 2009.Ministry of Transport of the People's Republic of China. Test methods of geosynthetics for highway engineering: JTGE 50−2006[S]. Beijing: China Communications Press, 2009. (in Chinese) [23] CHANG J Y, FENG S J. Dynamic shear behaviors of textured geomembrane/nonwoven geotextile interface under cyclic loading[J]. Geotextiles and Geomembranes, 2021, 49(2): 388-398. doi: 10.1016/j.geotexmem.2020.10.010 [24] 陈瑞锋, 闫炜炀, 刘晓凤, 等. 不同含水率下赤泥改良土的动弹模及阻尼比研究[J]. 硅酸盐通报, 2017, 36(8): 2810-2815.CHEN R F, YAN W Y, LIU X F, et al. Study of dynamic modulus and damping ratio of loess solidified by red mud under different water content[J]. Bulletin of the Chinese Ceramic Society, 2017, 36(8): 2810-2815. (in Chinese with English abstract [25] 吴孟桃, 刘方成, 陈巨龙, 等. 含水率对大应变下橡胶砂动剪模量和阻尼比的影响[J]. 岩土力学, 2018, 39(3): 803-814.WU M T, LIU F C, CHEN J L, et al. Influence of water content on dynamic shear modulus and damping ratio of rubber-sand mixture under large strains[J]. Rock and Soil Mechanics, 2018, 39(3): 803-814. (in Chinese with English abstract [26] 黄伟, 邱鹏, 赵鲁卿, 等. 钢渣−土混拌基层材料试验研究及微观机理分析[J]. 土木与环境工程学报(中英文), 2020, 42(4): 44-52. doi: 10.11835/j.issn.2096-6717.2020.037HUANG W, QIU P, ZHAO L Q, et al. Experimental study and micro-mechanism analysis of steel slag-soil mixed road base material[J]. Journal of Civil and Environmental Engineering, 2020, 42(4): 44-52. (in Chinese with English abstract doi: 10.11835/j.issn.2096-6717.2020.037 [27] 罗文俊, 王海洋, 刘焕强, 等. 不同含水率红粘土的抗剪强度试验研究[J]. 华东交通大学学报, 2020, 37(1): 119-126.LUO W J, WANG H Y, LIU H Q, et al. Experimental study on shear strength of red clay with different moisture content[J]. Journal of East China Jiaotong University, 2020, 37(1): 119-126. (in Chinese with English abstract [28] MAGHOOL F, ARULRAJAH A, MIRZABABAEI M, et al. Interface shear strength properties of geogrid-reinforced steel slags using a large-scale direct shear testing apparatus[J]. Geotextiles and Geomembranes, 2020, 48(5): 625-633. doi: 10.1016/j.geotexmem.2020.04.001 [29] AGHILI E, HOSSEINPOUR I, JAMSHIDI CHENARI R, et al. Behavior of granular column-improved clay under cyclic shear loading[J]. Transportation Geotechnics, 2021, 31: 100654. doi: 10.1016/j.trgeo.2021.100654 [30] 肖杰, 龙晨杰, 何建刚, 等. 大掺量激活钢渣微粉−水泥稳定碎石性能及微观特性[J]. 中国公路学报, 2021, 34(10): 204-215. doi: 10.3969/j.issn.1001-7372.2021.10.017XIAO J, LONG C J, HE J G, et al. Performance and micro characteristics of cement stabilized macadam with a large amount of activated steel slag powder[J]. China Journal of Highway and Transport, 2021, 34(10): 204-215. (in Chinese with English abstract doi: 10.3969/j.issn.1001-7372.2021.10.017 [31] 王丽艳, 李劲松, 陶云翔, 等. 废弃钢渣回填土工格栅加筋挡土墙的抗震性能振动台试验[J]. 中国公路学报, 2021, 34(1): 35-46. doi: 10.3969/j.issn.1001-7372.2021.01.004WANG L Y, LI J S, TAO Y X, et al. Shaking table tests on seismic behavior of geogrid-reinforced retaining wall with waste steel slag backfill[J]. China Journal of Highway and Transport, 2021, 34(1): 35-46. (in Chinese with English abstract doi: 10.3969/j.issn.1001-7372.2021.01.004 [32] SUN X S, LI Y J, WEI X L, et al. High contents of steel slag in the road concrete: Hydration mechanism, mechanical property and durability performance[J]. Construction and Building Materials, 2023, 400: 132703. doi: 10.1016/j.conbuildmat.2023.132703 [33] 张冰冰, 刘杰, 阿肯江·托呼提, 等. 土工格室加固风积沙路基不同深度动力响应试验研究[J]. 地质科技通报, 2022, 41(6): 308-315.ZHANG B B, LIU J, AKJ·T H T , et al. Experimental study on the dynamic response of aeolian sand subgrade reinforced by geocells at different depths[J]. Bulletin of Geological Science and Technology, 2022, 41(6): 308-315. (in Chinese with English abstract [34] 蒋婷婷, 潘华利, 艾一帆, 等. 冻融循环及含水率对冰碛土力学特性影响[J]. 地质科技通报, 2024, 43(2): 238-252.JIANG T T, PAN H L, AI Y F, et al. Effect of freeze-thaw cycles and water content on the mechanical properties of moraine soil[J]. Bulletin of Geological Science and Technology, 2024, 43(2): 238-252. (in Chinese with English abstract [35] 王泽成, 李栋伟, 张潮潮, 等. 考虑含水率对人工冻结红黏土力学特性的影响[J]. 地质科技通报, 2022, 41(6): 287-293.WANG Z C, LI D W, ZHANG C C, et al. Effect of water content on the mechanical properties of artificially frozen red clay[J]. Bulletin of Geological Science and Technology, 2022, 41(6): 287-293. (in Chinese with English abstract [36] 李福栋. 钢渣稳定粉质黏土的小应变动力特性试验研究[D]. 沈阳: 沈阳建筑大学, 2019.LI F D. Experimental study on small strain dynamic characteristics of steel slag stabilized silty clay[D]. Shenyang: Shenyang Jianzhu University, 2019. (in Chinese with English abstract [37] 南雪丽, 杨旭, 张宇, 等. 钢渣−矿渣基胶凝材料的协同水化机理[J]. 建筑材料学报, 2024, 27(4): 366-374. doi: 10.3969/j.issn.1007-9629.2024.04.011NAN X L, YANG X, ZHANG Y, et al. Synergistic hydration mechanism of steel slag-slag based cementitious material[J]. Journal of Building Materials, 2024, 27(4): 366-374. (in Chinese with English abstract doi: 10.3969/j.issn.1007-9629.2024.04.011 [38] 崔雯雯, 董晓强, 刘晓勇, 等. 赤泥基胶凝材料的水化动力学过程及其水化机制研究[J]. 岩土力学, 2025, 46(3): 867-880.CUI W W, DONG X Q, LIU X Y, et al. Hydration kinetics and hydration mechanism of red mud-based cementitious materials[J]. Rock and Soil Mechanics, 2025, 46(3): 867-880. (in Chinese with English abstract [39] 张刘阳, 陈潇, 吕国明, 等. 钢渣特性随粒级分布的规律研究[J]. 材料导报, 2025, 39(3): 133-140.ZHANG L Y, CHEN X, LÜ G M, et al. Study on the law of steel slag characteristics with particle size distribution[J]. Materials Reports, 2025, 39(3): 133-140. (in Chinese with English abstract [40] YIN C S, WANG H L, LIU X M, et al. Monotonic and cyclic mechanical characteristics of reconstituted soil with high liquid limit reinforced by steel slag[J]. Bulletin of Engineering Geology and the Environment, 2025, 84(3): 149. doi: 10.1007/s10064-025-04176-4 -

下载:

下载: