Numerical simulation on heat exchange performance of coaxical borehole heat exchanger

-

摘要:

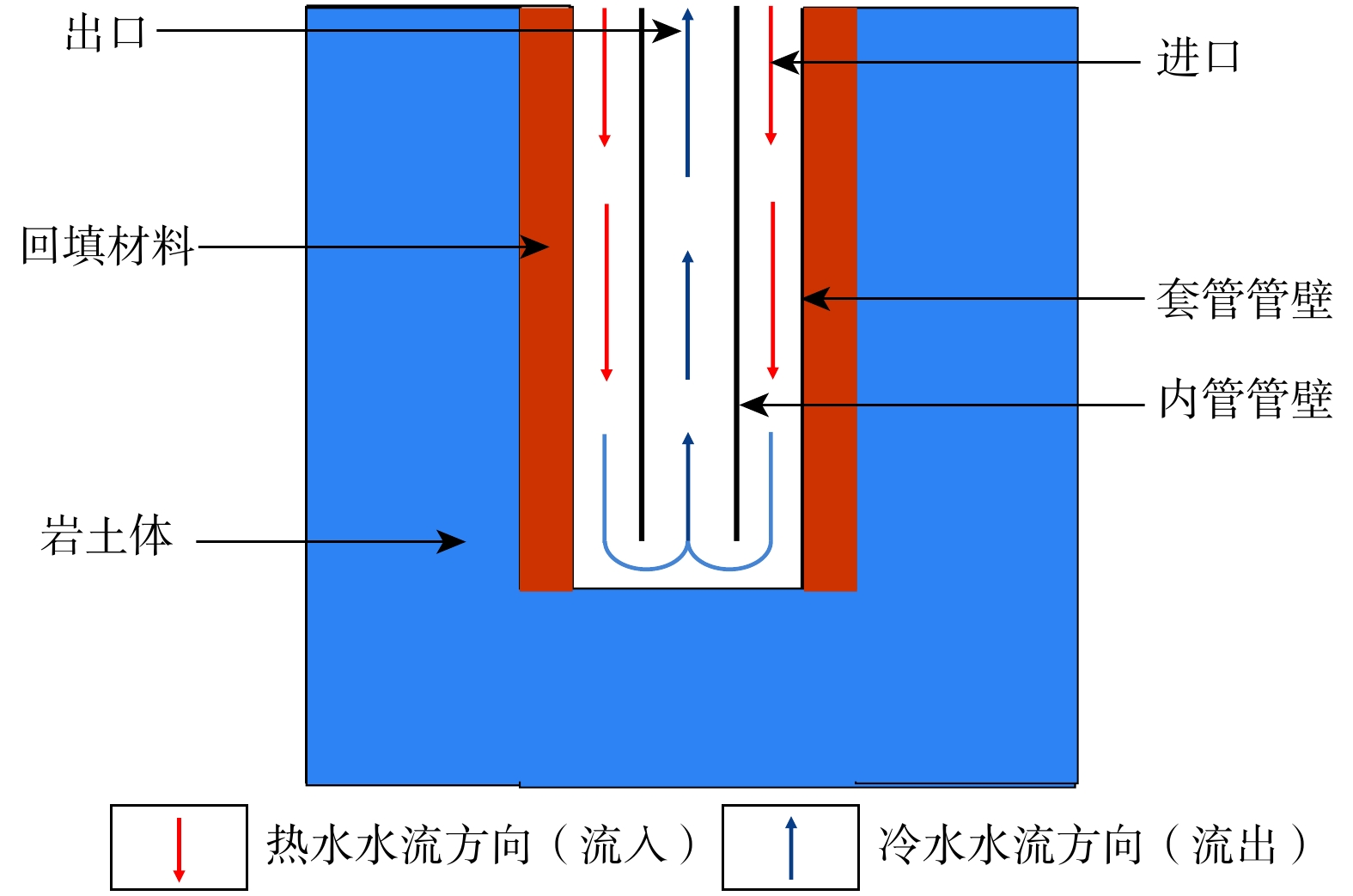

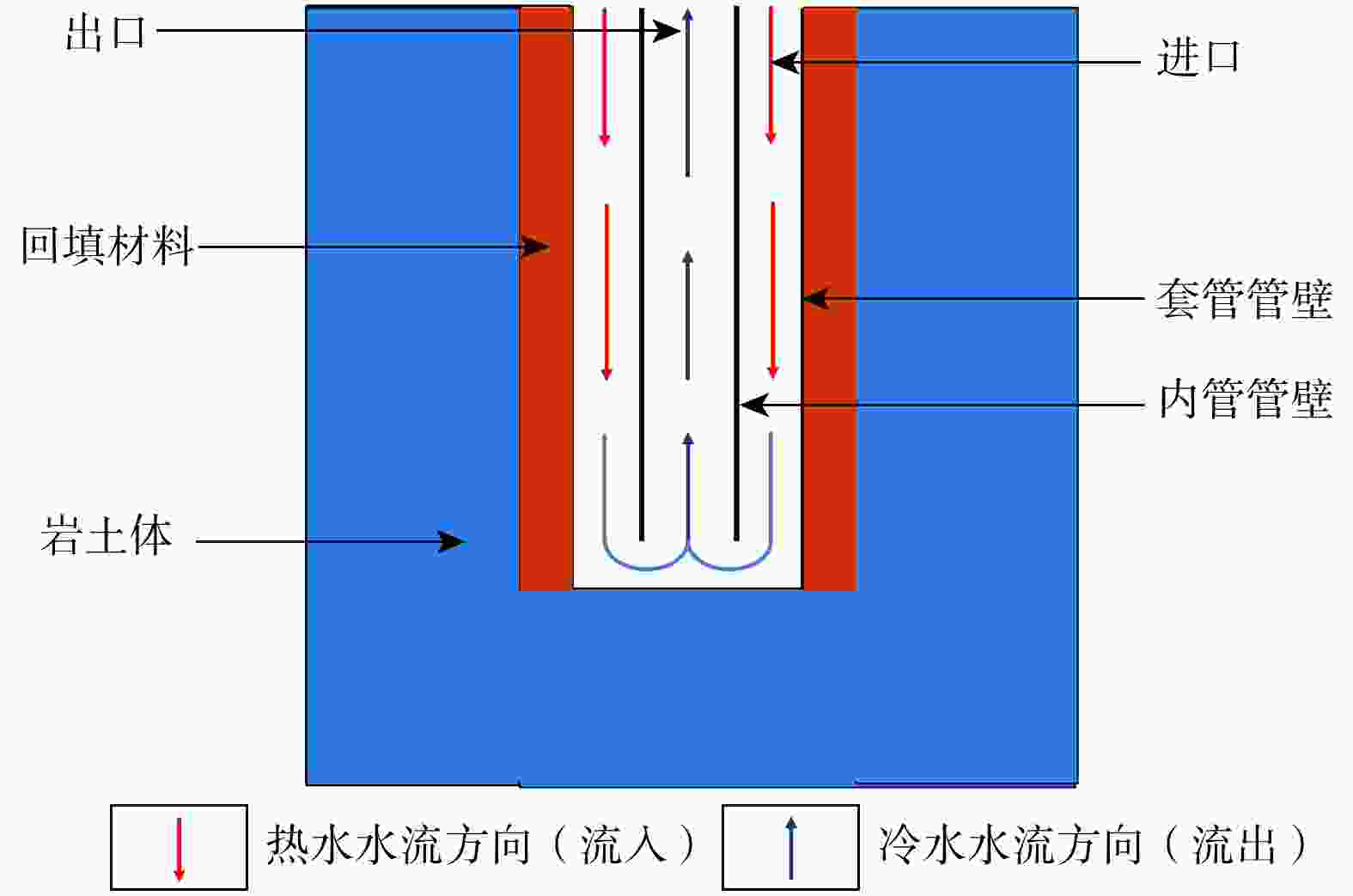

浅层地热能是一种清洁、稳定的可再生能源,地埋管地源热泵是开发利用浅层地热能进行建筑物供暖制冷的常用技术。地埋管换热器作为换热主体,目前常用的形式为U型的PE管换热器。然而,随着新材料新技术的发展和突破,地埋管换热器材料及埋管类型对于换热效率的提升具有一定的改善作用。因此,开展不同材料及埋管类型换热性能研究具有一定的工程实践意义。在浅层地热能开发利用中,套管式地埋管换热器的研究应用较少。以浅层套管式地埋管换热器为研究对象,开展换热性能数值模拟研究,分析了套管式地埋管换热器的换热性能及其敏感性因素,同U型地埋管换热器进行了换热效果的对比研究。结果表明:套管式地埋管换热器换热性能的敏感性因素强弱依次为进口温度、土壤初始温度、循环流量、套管及内管材料、回填材料导热系数;同等条件下,U型地埋管换热器换热效果比套管式地埋管换热器高8.57%;当套管式地埋管换热器的套管为钢材、内管为绝热材料时,其换热效果较U型地埋管换热器提高了21.64%。研究成果可为浅层埋管技术的研究及应用提供参考依据。

Abstract:Objective Shallow geothermal energy is a clean and stable renewable energy source. Ground-coupled heat pumps represents are a commonly used technology for developing and utilizing shallow geothermal energy in building heating and cooling systems. This technology extracts heat from the subsurface without pumping groundwater; thus causing minimal disturbance to the underground environment. The borehole heat exchanger serves as the primary component of heat exchange in ground-coupled heat pump systems, with the U-shaped configuration being the most prevalent. However, research and application of coaxial borehole heat exchangers in shallow geothermal energy remain relatively limited.

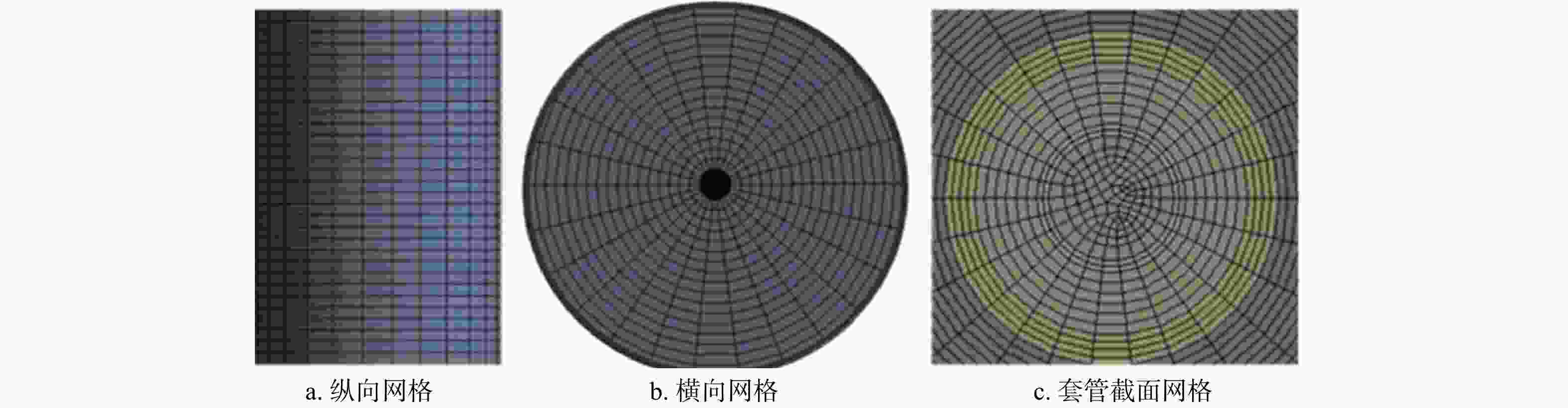

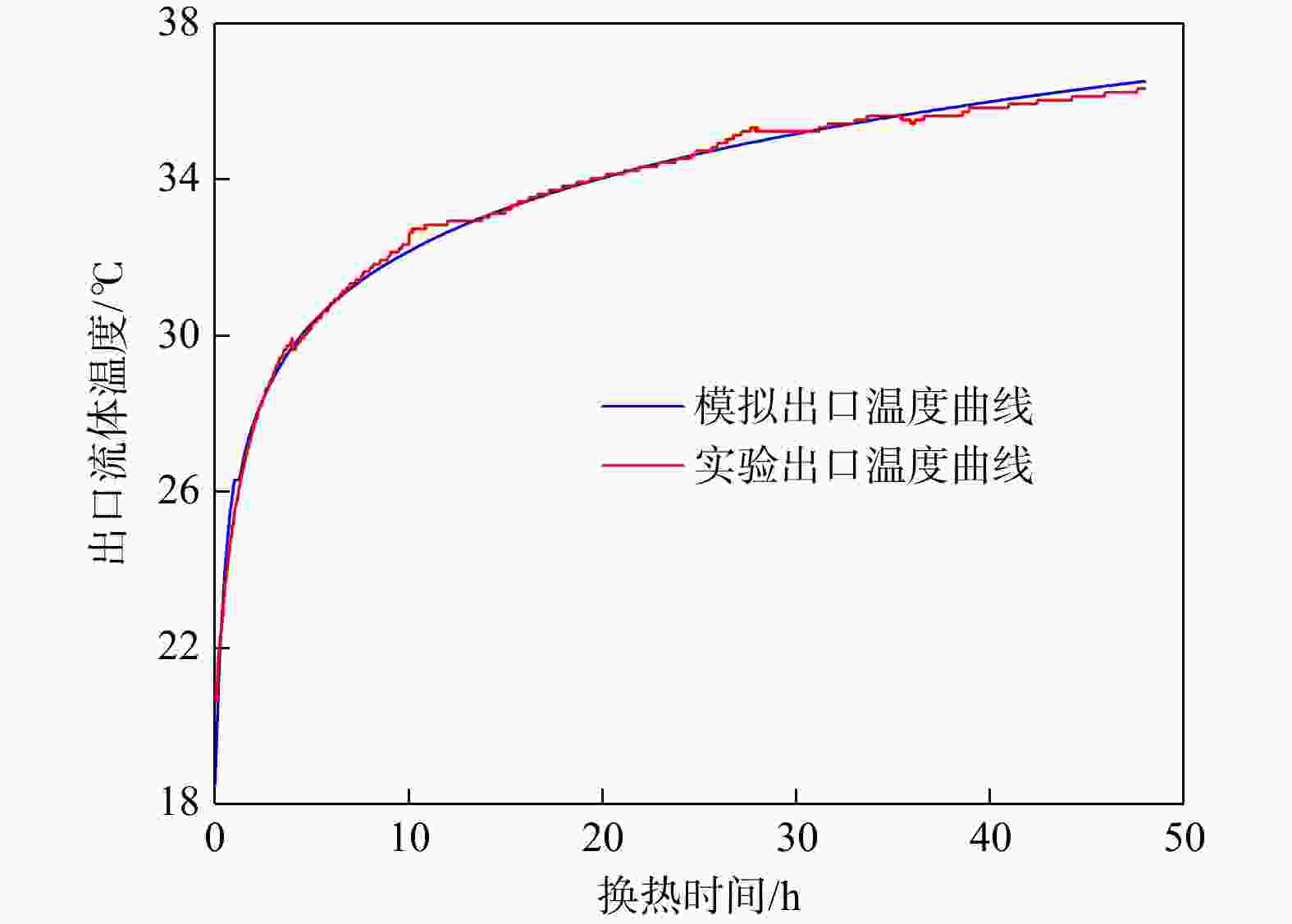

Methods This study focuses on the shallow coaxial borehole heat exchanger and conducts numerical simulations to investigate their heat exchange performance, analyze sensitivity factors, and compare their efficiency with that of a U-shaped borehole heat exchanger.

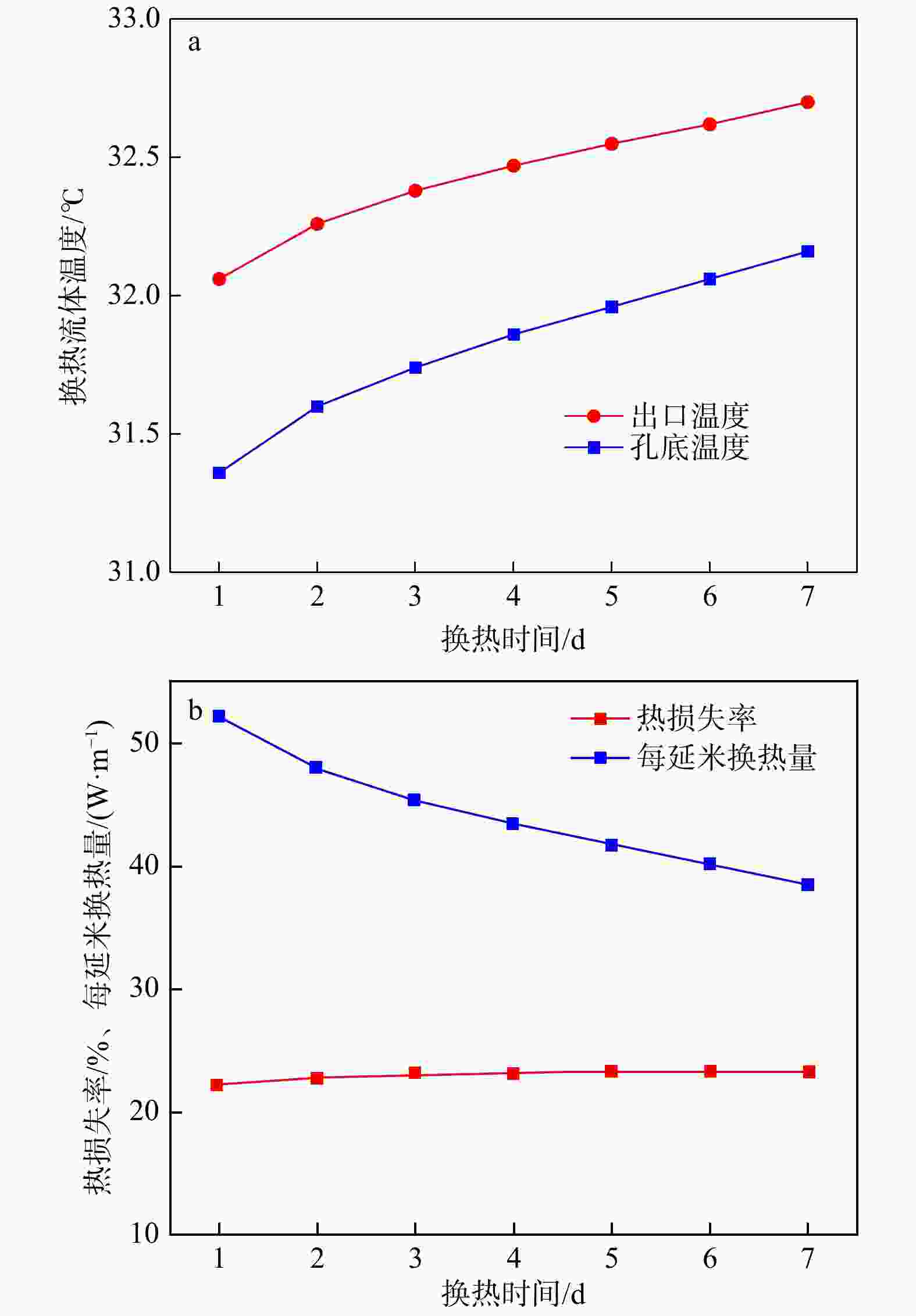

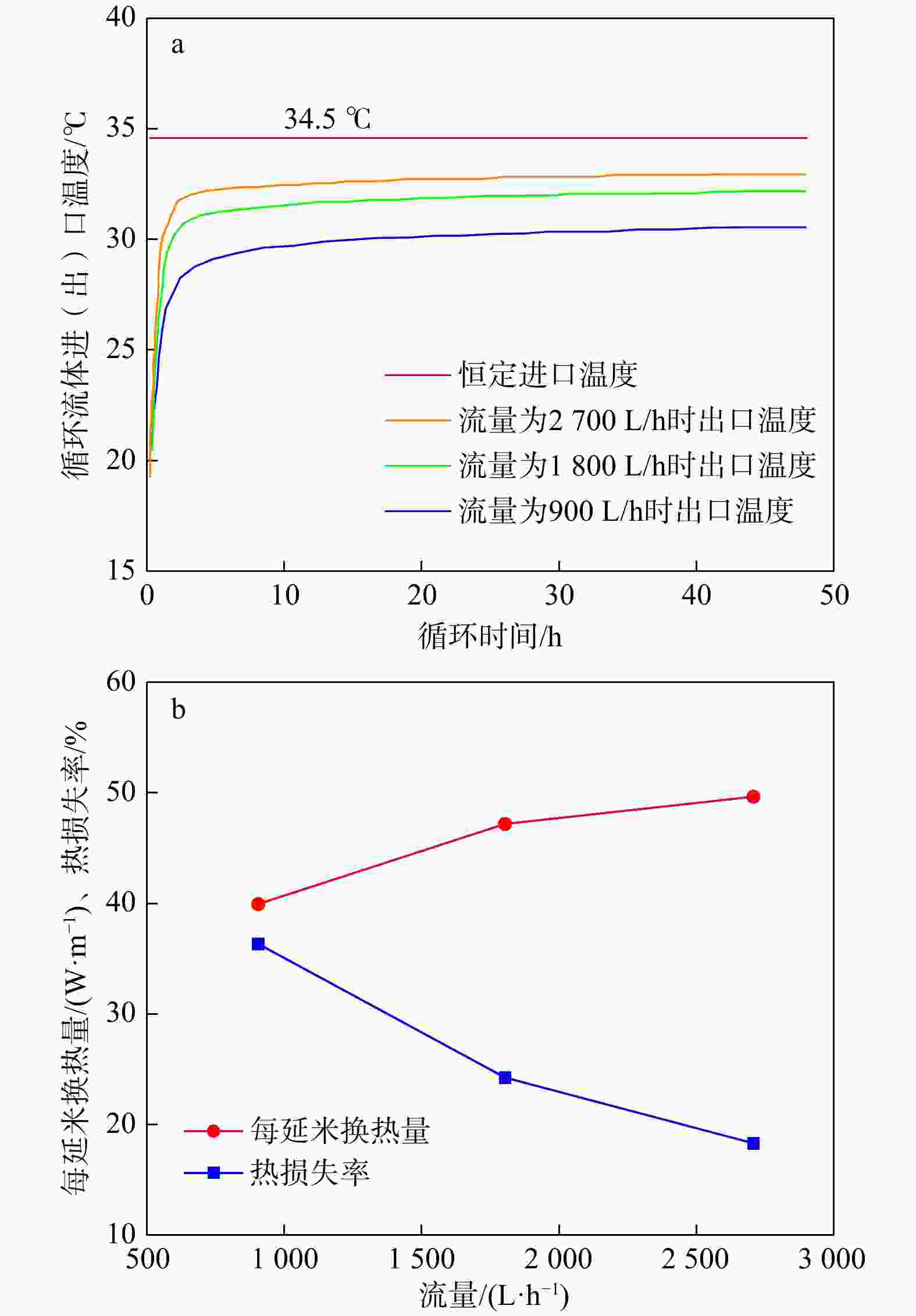

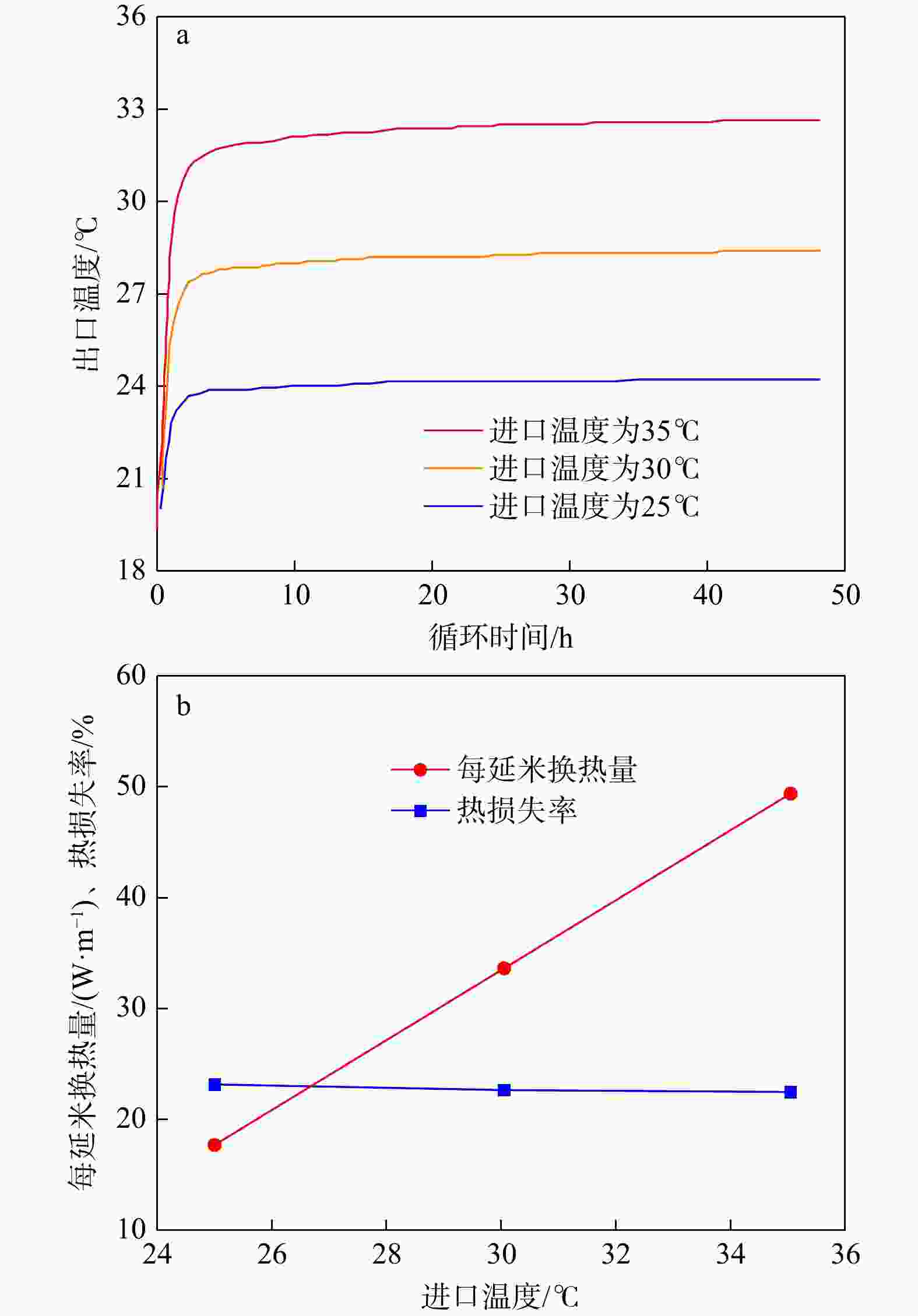

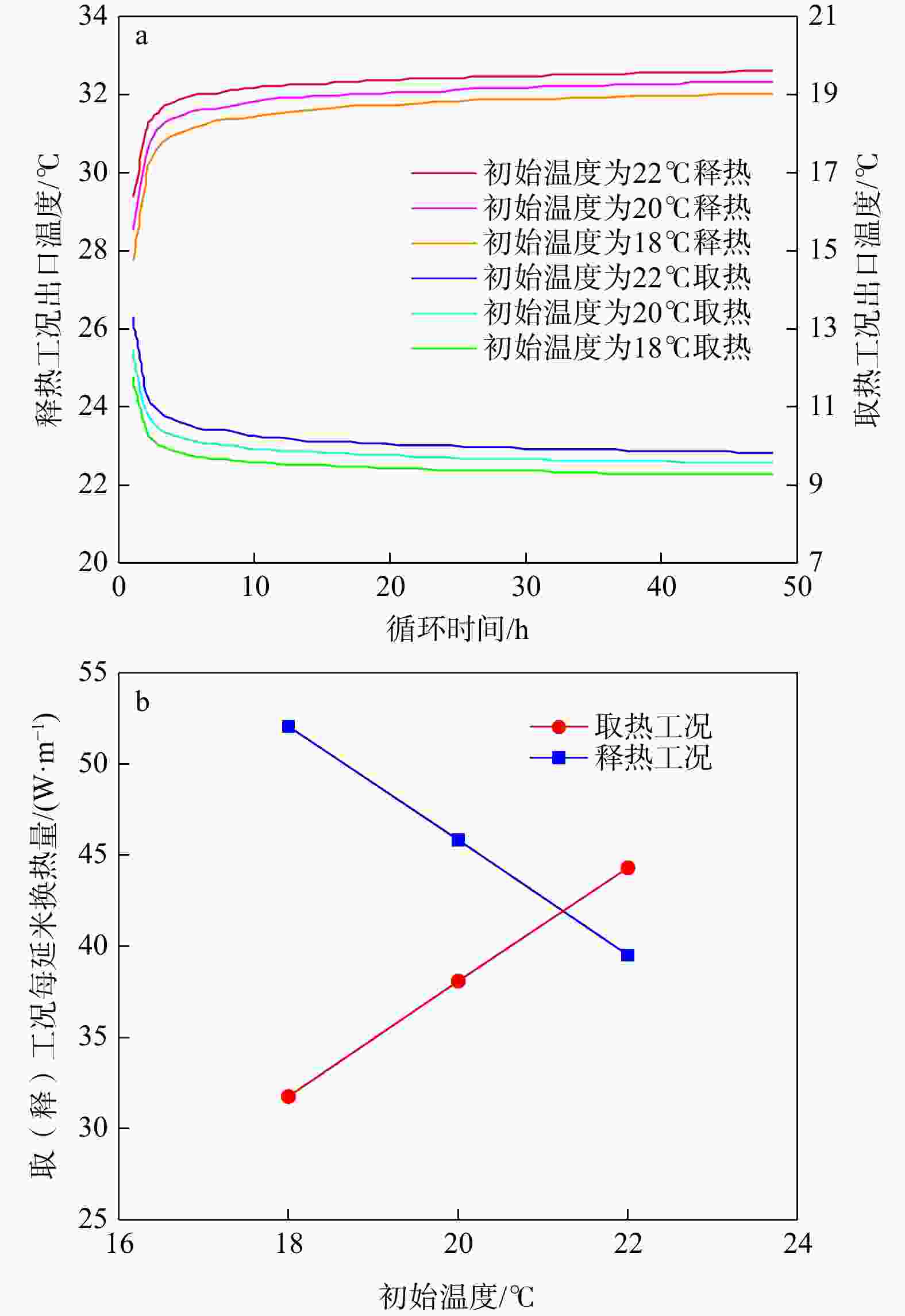

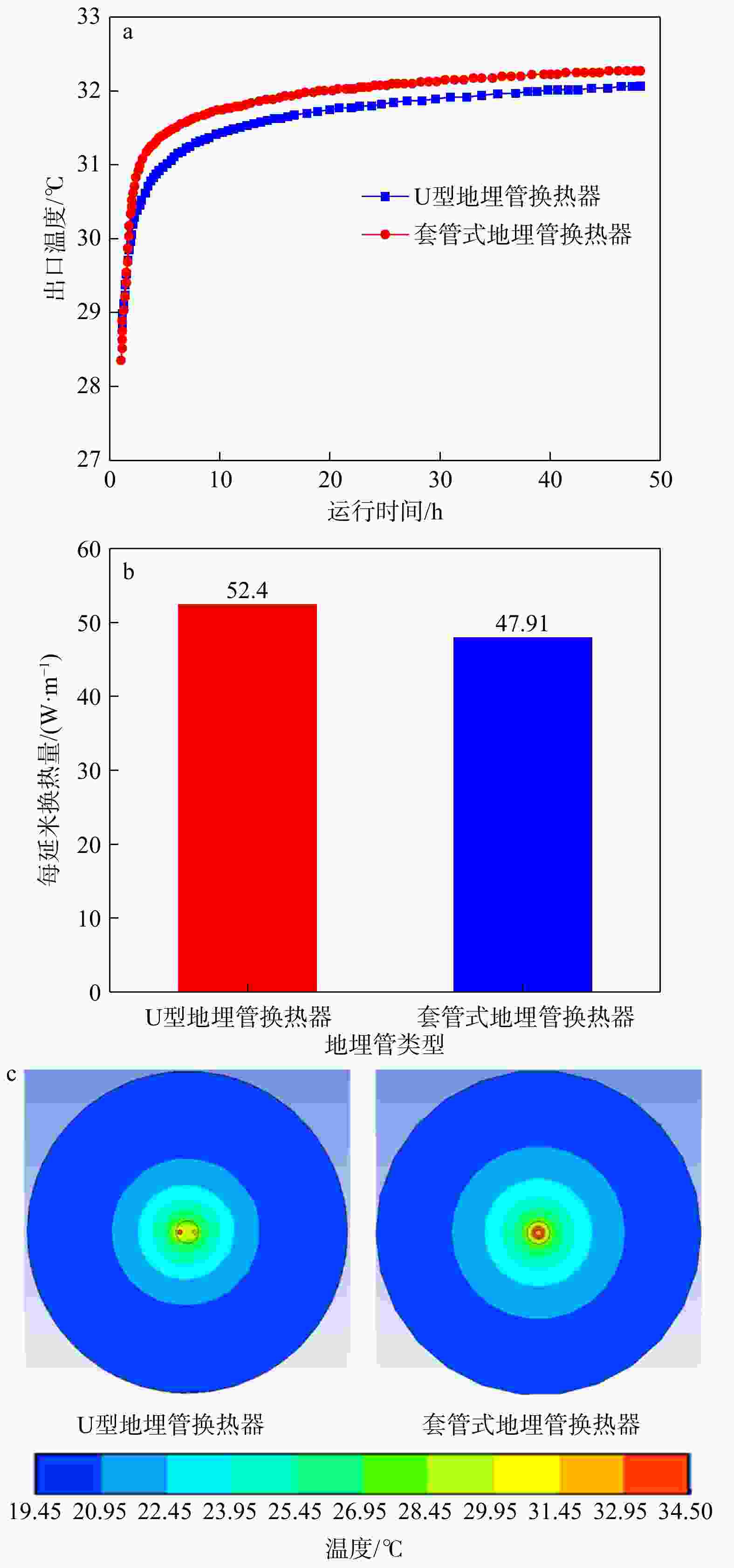

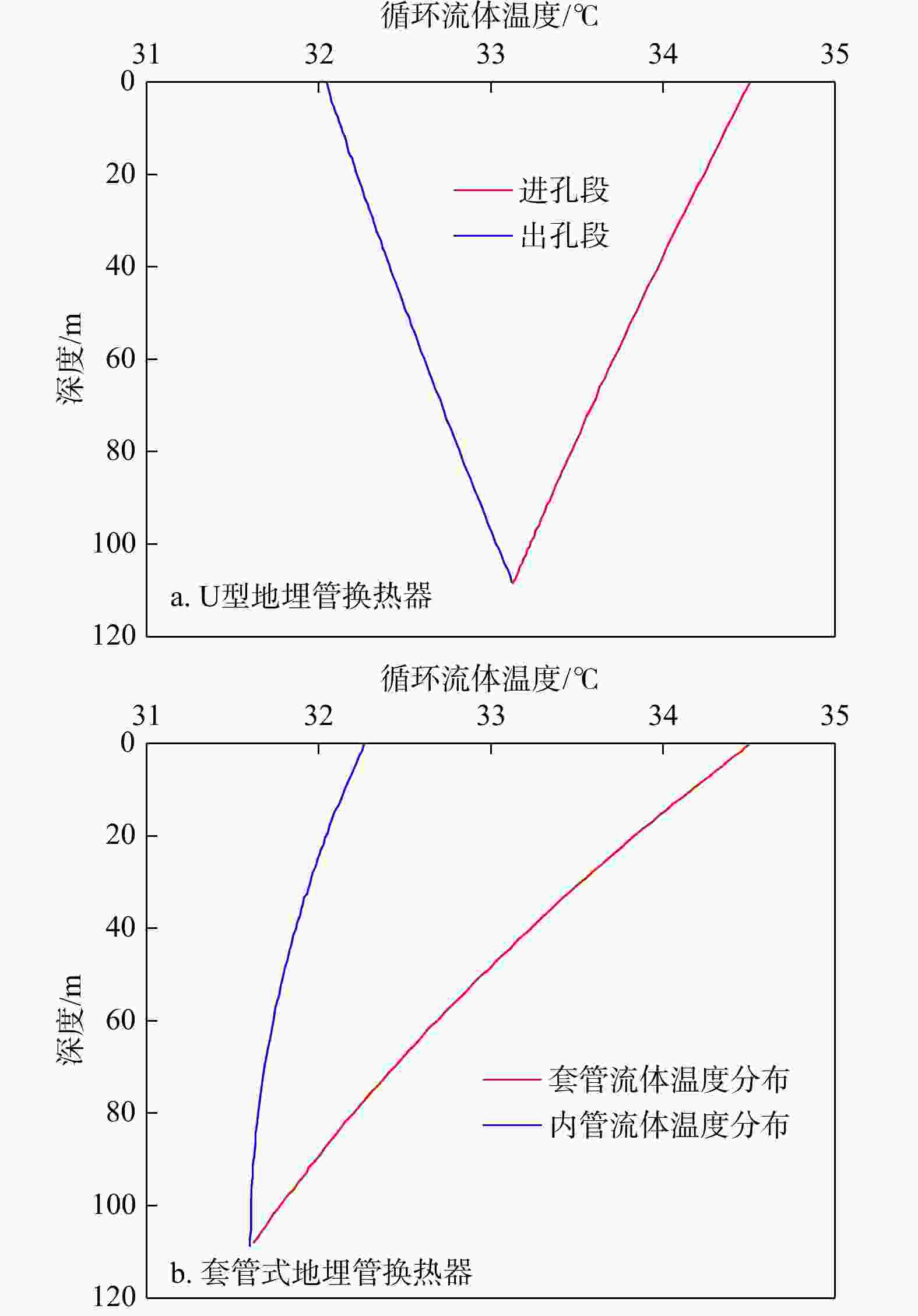

Results The findings demonstrate that when traditional PE pipes are employed for both the inner and outer pipes of a coaxial borehole heat exchanger, thermal short-circuiting occurs between the annular fluid and the inner pipe fluid, resulting in a 23% reduction in heat exchange efficiency. The sensitivity factors influencing coaxial borehole heat exchangers performance are ranked as follows: Inlet temperature, initial soil temperature, circulating flow rate, thermal conductivity of casing and inner pipe materials, and thermal conductivity of backfill material. Under identical conditions, the U-shaped borehole heat exchanger exhibits an 8.57% higher heat exchange efficiency compared to coaxial borehole heat exchanges. However, when a coaxial borehole heat exchanger's casing is constructed from steel and its inner pipe is insulated, its heat exchange efficiency exceeds that of the U-shaped borehole heat exchanger by 21.64%.

Conclusion The research results can provide a reference for the research and application of shallow-buried pipe technology.

-

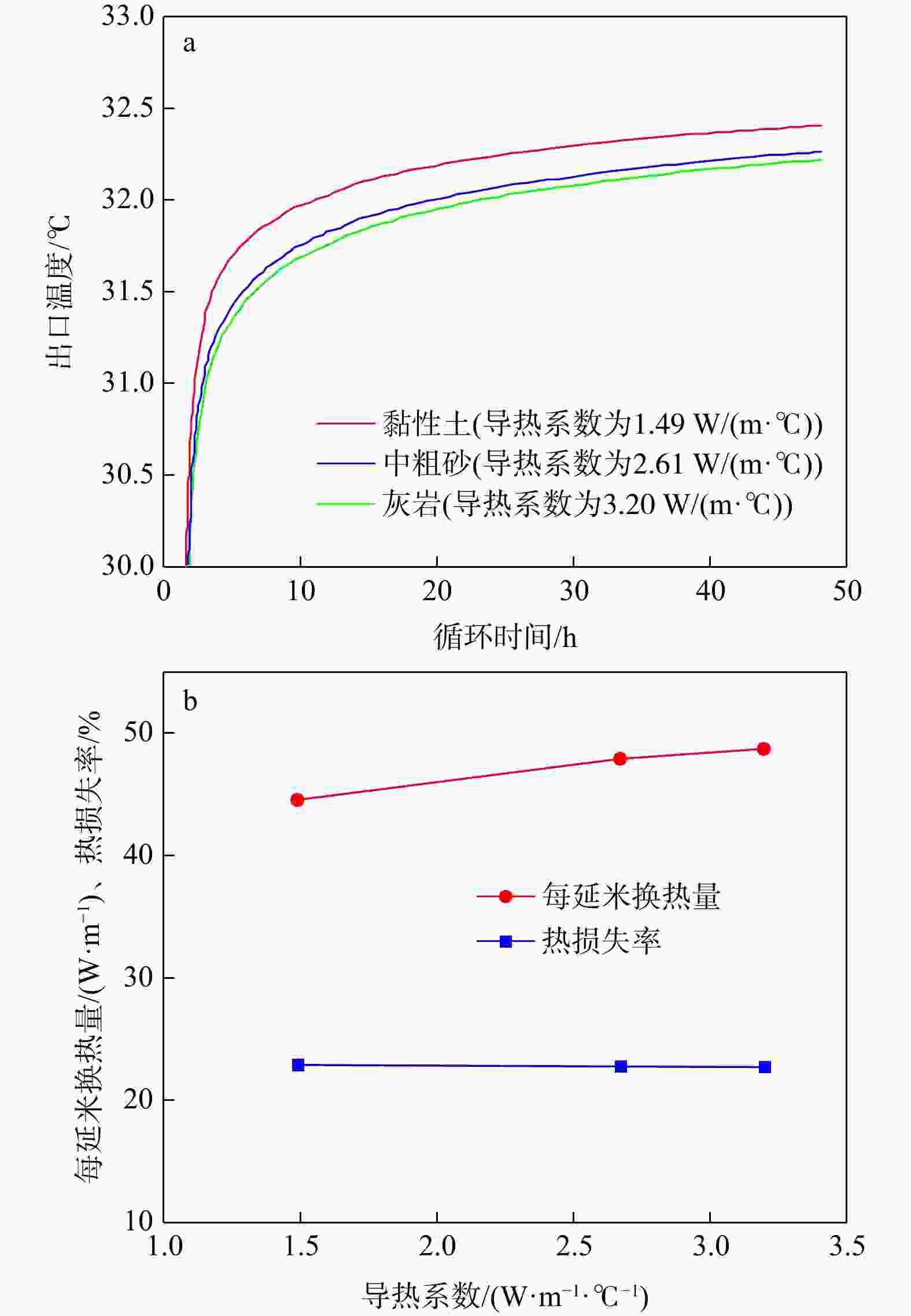

图 10 不同回填材料导热系数下出口温度随循环时间变化(a)以及每延米换热量和热损失率随回填材料导热系数变化(b)

Figure 10. Outlet temperature variation with circulating time under different thermal conductivities of backfill materials (a) and heat exchange rate per meter and heat loss rate variation with thermal conductivities of backfill materials (b)

表 1 套管式地埋管换热器模型尺寸参数

Table 1. Size parameters of coaxial borehole heat exchanger model

尺寸参数 数值/mm 套管外径 90 套管壁厚 8.2 套管长度 10850 内管外径 40 内管壁厚 3.7 内管长度 10800 钻孔直径 150 岩土直径 400 表 2 套管式地埋管换热器模型热物性参数[21]

Table 2. Thermophysical parameters of coaxial borehole heat exchanger model

热物性参数 密度/

(kg·m−3)比热容/

(J·kg−1·℃−1)导热系数/

(W·m−1·℃−1)水 998.2 4182 0.6 PE管 980 2300 0.42 回填材料(中粗砂) 1900 1145 2.61 地层 2100 957 2.10 -

[1] GONG S. Research on ground source heat pump technology in China[J]. International Core Journal of Engineering, 2020, 6(3): 198-203. [2] LUO J, ROHN J, BAYER M, et al. Heating and cooling performance analysis of a ground source heat pump system in southern Germany[J]. Geothermics, 2015, 53: 57-66. doi: 10.1016/j.geothermics.2014.04.004 [3] 王亚超, 窦斌, 喻勇, 等. 不同冷却方式下高温花岗岩巴西劈裂及声发射特性试验研究[J]. 地质科技通报, 2022, 41(3): 200-207.WANG Y C, DOU B, YU Y, et al. Experimental study on Brazilian split test and acoustic emission characteristics of high temperature granite under different cooling methods[J]. Bulletin of Geological Science and Technology, 2022, 41(3): 200-207. (in Chinese with English abstract [4] ZHANG L F, LUO X W, HUANG G S, et al. Comparative analysis of U-pipe location on the sizing of borehole heat exchangers[J]. Applied Thermal Engineering, 2019, 150: 666-673. doi: 10.1016/j.applthermaleng.2019.01.017 [5] ZHU Z N, TIAN H, JIANG G S, et al. Effects of high temperature on the mechanical properties of Chinese marble[J]. Rock Mechanics and Rock Engineering, 2018, 51(6): 1937-1942. doi: 10.1007/s00603-018-1426-0 [6] 段新胜, 顾湘, 李鹏, 等. 加热过程间断的热响应试验数据处理方法研究[J]. 太阳能学报, 2018, 39(10): 2685-2690.DUAN X S, GU X, LI P, et al. Study on data processing method for thermal response test of discontinuous heating process[J]. Acta Energiae Solaris Sinica, 2018, 39(10): 2685-2690. (in Chinese with English abstract [7] ARESTI L, CHRISTODOULIDES P, FLORIDES G. A review of the design aspects of ground heat exchangers[J]. Renewable and Sustainable Energy Reviews, 2018, 92: 757-773. doi: 10.1016/j.rser.2018.04.053 [8] LIU J, WANG F H, CAI W L, et al. Numerical study on the effects of design parameters on the heat transfer performance of coaxial deep borehole heat exchanger[J]. International Journal of Energy Research, 2019, 43(12): 6337-6352. doi: 10.1002/er.4357 [9] 林华颖, 裴鹏, 邹行, 等. 贵州省毕节市米底河地热特征及形成机理[J]. 地质科技通报, 2023, 42(3): 281-288.LIN H Y, PEI P, ZOU H, et al. Geothermal characteristics and formation mechanism of the Medi River in Bijie City, Guizhou Province[J]. Bulletin of Geological Science and Technology, 2023, 42(3): 281-288. (in Chinese with English abstract [10] 薛玉伟, 季民, 李新国, 等. 单U、双U型埋管换热器换热性能与经济性研究[J]. 太阳能学报, 2006, 27(4): 410-414.XUE Y W, JI M, LI X G, et al. Heat performance research and economical analysis of single U shaped and double U shaped vertical borehole heat exchanger[J]. Acta Energiae Solaris Sinica, 2006, 27(4): 410-414. (in Chinese with English abstract [11] DUUS K, SCHMITZ G. Experimental investigation of sustainable and energy efficient management of a geothermal field as a heat source and heat sink for a large office building[J]. Energy and Buildings, 2021, 235: 110726. doi: 10.1016/j.enbuild.2021.110726 [12] VIEIRA A, ALBERDI-PAGOLA M, CHRISTODOULIDES P, et al. Characterisation of ground thermal and thermo-mechanical behaviour for shallow geothermal energy applications[J]. Energies, 2017, 10(12): 2044. doi: 10.3390/en10122044 [13] LUO J, ROHN J, XIANG W, et al. Experimental investigation of a borehole field by enhanced geothermal response test and numerical analysis of performance of the borehole heat exchangers[J]. Energy, 2015, 84: 473-484. doi: 10.1016/j.energy.2015.03.013 [14] WAGNER V, BAYER P, KÜBERT M, et al. Numerical sensitivity study of thermal response tests[J]. Renewable Energy, 2012, 41: 245-253. doi: 10.1016/j.renene.2011.11.001 [15] HU J Z. An improved analytical model for vertical borehole ground heat exchanger with multiple-layer substrates and groundwater flow[J]. Applied Energy, 2017, 202: 537-549. doi: 10.1016/j.apenergy.2017.05.152 [16] ZHANG X P, HAN Z W, JI Q, et al. Thermal response tests for the identification of soil thermal parameters: A review[J]. Renewable Energy, 2021, 173: 1123-1135. doi: 10.1016/j.renene.2020.12.028 [17] WANG H J, QI C Y, DU H P, et al. Thermal performance of borehole heat exchanger under groundwater flow: A case study from Baoding[J]. Energy and Buildings, 2009, 41(12): 1368-1373. doi: 10.1016/j.enbuild.2009.08.001 [18] LUO J, TUO J S, HUANG W, et al. Influence of groundwater levels on effective thermal conductivity of the ground and heat transfer rate of borehole heat exchangers[J]. Applied Thermal Engineering, 2018, 128: 508-516. doi: 10.1016/j.applthermaleng.2017.08.148 [19] ZHANG L L, ZHAO L, YANG L. Analyses on soil temperature responses to intermittent heat rejection from BHEs in soils with groundwater advection[J]. Energy and Buildings, 2015, 107: 355-365. doi: 10.1016/j.enbuild.2015.08.040 [20] HEFNI M A, XU M H, ZUETER A F, et al. A 3D space-marching analytical model for geothermal borehole systems with multiple heat exchangers[J]. Applied Thermal Engineering, 2022, 216: 119027. doi: 10.1016/j.applthermaleng.2022.119027 [21] PAN A Q, LU L, CUI P, et al. A new analytical heat transfer model for deep borehole heat exchangers with coaxial tubes[J]. International Journal of Heat and Mass Transfer, 2019, 141: 1056-1065. doi: 10.1016/j.ijheatmasstransfer.2019.07.041 [22] LUO Y Q, YU J H, YAN T, et al. Improved analytical modeling and system performance evaluation of deep coaxial borehole heat exchanger with segmented finite cylinder-source method[J]. Energy and Buildings, 2020, 212: 109829. doi: 10.1016/j.enbuild.2020.109829 [23] 王硕, 黄可钦, 王胜蓝, 等. 同轴套管式深埋管换热器换热性能研究[J]. 制冷与空调, 2019, 19(4): 23-28.WANG S, HUANG K Q, WANG S L, et al. Research on heat transfer performance of coaxial double-pipe deep borehole heat exchanger[J]. Refrigeration and Air-Conditioning, 2019, 19(4): 23-28. (in Chinese with English abstract [24] 王硕, 殷元生, 黄可钦, 等. 同轴套管深埋管换热器延米换热量变化规律的研究[J]. 工业加热, 2019, 48(2): 5-9.WANG S, YIN Y S, HUANG K Q, et al. Research on the change of heat transfer rate per meter in deep coaxial borehole heat exchanger[J]. Industrial Heating, 2019, 48(2): 5-9. (in Chinese with English abstract [25] 张兵兵. 中深层套管式地埋管换热器与地源侧水系统能效研究[D]. 济南: 山东建筑大学, 2019.ZHANG B B. Study on energy efficiency of deep borehole casing type buried pipe heat exchanger and ground source side water system[D]. Jinan: Shandong Jianzhu University, 2019. (in Chinese with English abstract [26] 李鹏程. 中深层地热源热泵套管式地埋管换热器传热特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.LI P C. Research on heat transfer characteristics of casing ground heat exchanger with medium and deep ground source heat pump[D]. Harbin: Harbin Institute of Technology, 2018. (in Chinese with English abstract [27] 谢宗标. 同轴深井套管式地埋管换热器岩土热物性实验分析研究[D]. 合肥: 安徽建筑大学, 2017.XIE Z B. Experimental study on geothermal properties of coaxial deep-well casing-shaped underground heat exchanger[D]. Hefei: Anhui Jianzhu University, 2017. (in Chinese with English abstract [28] 季丰旭. 同轴式地下热交换器及其传热模型研究[D]. 长春: 吉林大学, 2007.JI F X. Study on coaxial underground heat exchanger and heat transfer model[D]. Changchun: Jilin University, 2007. (in Chinese with English abstract [29] 宁轶. 基于CFD的套管式地埋管的换热影响因素分析[D]. 武汉: 华中科技大学, 2018.NING Y. The analysis of influence factors of the coaxial tube borehole heat exchanger baced on CFD[D]. Wuhan: Huazhong University of Science and Technology, 2018. (in Chinese with English abstract [30] 关鹏, 段新胜, 焦玉勇, 等. 同轴地埋管换热器岩土热响应试验研究[J]. 太阳能学报, 2022, 43(2): 55-61.GUAN P, DUAN X S, JIAO Y Y, et al. Experimental study on geotechnical thermal response test of coaxial borehole heat exchanger[J]. Acta Energiae Solaris Sinica, 2022, 43(2): 55-61. (in Chinese with English abstract [31] 张东海. 分层和渗流条件下竖直地埋管换热器传热特性研究[D]. 江苏徐州: 中国矿业大学, 2020.ZHANG D H. Investigation on heat transfer behavior of vertical ground heat exchangers in a layered subsurface in the presence of groundwater advection[D]. Xuzhou Jiangsu: China University of Mining and Technology, 2020. (in Chinese with English abstract [32] GEHLIN S. Thermal response test: Method development and evaluation[D]. Lulea, Sweden: Lulea University of Technology, 2002. [33] CAO D F, SHI B, ZHU H H, et al. A field study on the application of distributed temperature sensing technology in thermal response tests for borehole heat exchangers[J]. Bulletin of Engineering Geology and the Environment, 2019, 78(6): 3901-3915. doi: 10.1007/s10064-018-1407-2 [34] OH K, LEE S, PARK S, et al. Field experiment on heat exchange performance of various coaxial-type ground heat exchangers considering construction conditions[J]. Renewable Energy, 2019, 144: 84-96. doi: 10.1016/j.renene.2018.10.078 [35] LI P, GUAN P, ZHENG J, et al. Field test and numerical simulation on heat transfer performance of coaxial borehole heat exchanger[J]. Energies, 2020, 13(20): 5471. doi: 10.3390/en13205471 [36] LUO Y Q, CHENG N, XU G Z. Analytical modeling and thermal analysis of deep coaxial borehole heat exchanger with stratified-seepage-segmented finite line source method (S3-FLS)[J]. Energy and Buildings, 2022, 257: 111795. doi: 10.1016/j.enbuild.2021.111795 [37] ZHANG L F, HUANG G S, ZHANG Q, et al. An hourly simulation method for the energy performance of an office building served by a ground-coupled heat pump system[J]. Renewable Energy, 2018, 126: 495-508. doi: 10.1016/j.renene.2018.03.082 [38] PU L, QI D, XU L L, et al. Optimization on the performance of ground heat exchangers for GSHP using Kriging model based on MOGA[J]. Applied Thermal Engineering, 2017, 118: 480-489. doi: 10.1016/j.applthermaleng.2017.02.114 [39] ZHENG J, LI P, DOU B, et al. Impact research of well layout schemes and fracture parameters on heat production performance of enhanced geothermal system considering water cooling effect[J]. Energy, 2022, 255: 124496. doi: 10.1016/j.energy.2022.124496 [40] ARIAS-PENAS D, CASTRO-GARCÍA M P, REY-RONCO M A, et al. Determining the thermal diffusivity of the ground based on subsoil temperatures: Preliminary results of an experimental geothermal borehole study Q-THERMIE-UNIOVI[J]. Geothermics, 2015, 54: 35-42. doi: 10.1016/j.geothermics.2014.10.006 [41] YOON S, LEE S R, KIM M J, et al. Evaluation of stainless steel pipe performance as a ground heat exchanger in ground-source heat-pump system[J]. Energy, 2016, 113: 328-337. doi: 10.1016/j.energy.2016.07.057 -

下载:

下载: