Experimental study on interface frictional property between sand and concrete pipe jacking

-

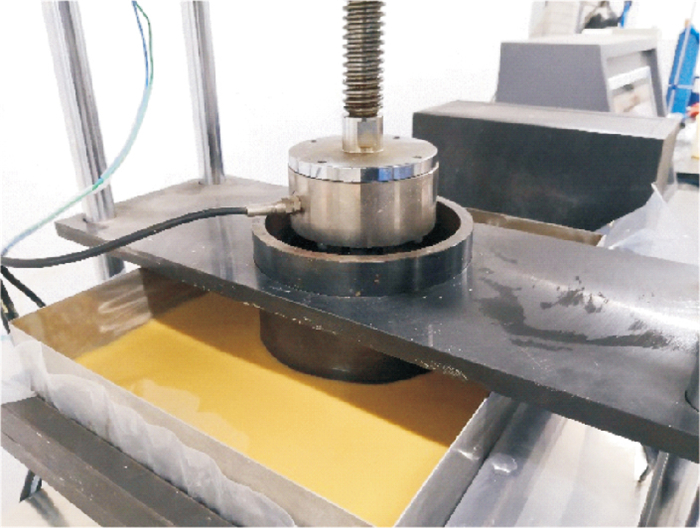

摘要: 为了揭示不同工况下混凝土顶管-砂土接触面剪切摩擦特性,确定管土、管浆摩擦系数,为顶管施工参数的选取及顶进力的计算提供指导与参考。采用直剪试验研究了5种砂土在不同法向压力、不同剪切速率及不同润滑状态下与混凝土管接触面的摩擦特性。试验结果表明:随着砂土颗粒粒径的增加,砂土与混凝土接触面剪切应力稳定值降低。随着法向应力的增加,砂土界面剪切应力达到峰值或稳定值时的剪切位移增加,同时界面剪切应力-剪切位移曲线的应变软化特性逐渐减弱,应变硬化趋势逐渐增强。无润滑条件下,随着法向应力的增加,剪切应力稳定值增量基本保持稳定或略有降低,泥浆润滑条件下,剪切应力稳定值增量增大;在较低法向压力下剪切速率对砂土剪切应力的影响较小;泥浆润滑条件下,砂土与混凝土接触面剪切应力可降低70%~80%,随着法向应力的增加,润滑效果降低。Abstract: To reveal the shear friction mechanical mechanism between concrete pipe jacking and sand, obtain the friction coefficient of pipe-soil and pipe-slurry, and provide guidance and reference for the selection of pipe jacking construction parameters and the calculation of jacking force.To that end, the shear friction behavior and mechanical mechanism were investigated between 5 types of sands and concrete pipe under different normal pressure, shear rate and lubrication state. The test results show that the stable value (residual value) of shear stress at the concrete-sand interface increases first and then decreases with the increase of sand particle size. With the increase of normal stress, the shear displacement when the shear stress of the concrete-sand interface reaches the peak or stable value increases. Meanwhile, the strain softening characteristic of the shear stress versus shear displacement curve gradually weakens and the strain hardening trend gradually obvious. Without lubrication, as the normal stress increases, the increment of shear stress stability value remains stable or slightly decreases. With slurry lubrication, the increment of shear stress stability value increases. Under lower normal pressure, the shear rate has little effect on the shear stress of sand.When using slurry lubrication, the stable value of shear stress at the concrete-sand interface can be reduced by 70%-80%, and the lubrication effect decreases with the increase of normal stress.

-

Key words:

- pipe-soil interface /

- frictional property /

- direct shear test /

- slurry lubrication

-

表 1 土样基本物理参数

Table 1. Basic physical parameters of soil samples

土样类型 粒度组成/% 最小干密度 最大干密度 控制干密度 饱和密度 > 2 mm [0.5, 2] mm (0.25, 0.5] mm (0.075, 0.25] mm ≤0.075 mm ρB/(g·cm-3) 砾砂 30 40 5 25 0 1.505 1.857 1.709 1.950 粗砂 5 50 5 40 0 1.628 1.875 1.717 1.949 中砂 5 35 15 45 0 1.647 1.844 1.698 1.954 细砂 5 25 0 70 0 1.609 1.855 1.663 1.965 粉砂 2 20 10 48 20 1.651 1.754 1.651 1.902 表 2 不同条件下接触面摩擦系数

Table 2. Friction coefficient of interface under different conditions

土样类型 不同法向应力下的摩擦系数 平均值 50 kPa 100 kPa 150 kPa 砾砂 干 0.600 0.570 0.587 0.586 饱和 0.561 0.557 0.558 0.559 泥浆润滑 0.137 0.143 0.218 0.166 粗砂 干 0.597 0.590 0.595 0.594 饱和 0.623 0.596 0.591 0.603 泥浆润滑 0.162 0.136 0.195 0.164 中砂 干 0.643 0.625 0.619 0.629 饱和 0.618 0.565 0.561 0.581 泥浆润滑 0.157 0.167 0.178 0.167 细砂 干 0.622 0.613 0.623 0.619 饱和 0.631 0.602 0.584 0.606 泥浆润滑 0.190 0.160 0.176 0.175 粉砂 干 0.646 0.612 0.603 0.620 饱和 0.621 0.600 0.588 0.603 泥浆润滑 0.207 0.189 0.224 0.207 -

[1] 唐培文. 大断面矩形顶管减阻技术应用研究: 以苏州综合管廊矩形顶管为例[J]. 地质科技通报, 2020, 39(2): 198-203. doi: 10.19509/j.cnki.dzkq.2020.0222Tang P W. Application of drag reduction technology of large section rectangular pipe jacking: A case study of rectangular jacking of Suzhou comprehensive pipe rack[J]. Bulletin of Geological Science and Technology, 2020, 39(2): 198-203(in Chinese with English abstract). doi: 10.19509/j.cnki.dzkq.2020.0222 [2] Haslem R F. Pipe-jacking forces from practice totheory: Proceedings of ICE north western association centenary conference in infrastructure renovation and waste control[C]. Manchester: Manstock, 1986. [3] O'Reilly M P, Rogers C D F. Pipe jacking forces: Proceedings of International conference on foundations and tunnels[C]. Edinburgh: Engineering Technics Press, 1987. [4] Milligan G W E, Norris P. Pipe-soil interaction during pipe jacking[J]. Proceedings of the ICE-GeotechnicalEngineering, 1999, 137(1): 27-44. [5] Sofianos A I, Loukas P, Chantzakos C. Pipe jacking: A sewer under Athens[J]. Tunnelling and Underground Space Technology, 2004, 19(2): 193-203. doi: 10.1016/S0886-7798(03)00108-1 [6] 张鹏, 马保松, 曾聪, 等. 基于管土接触特性的顶进力计算模型分析[J]. 岩土工程学报, 2017, 39(2): 244-249. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201702009.htmZhang P, Ma B S, Zeng C, et al. Numerical model for jacking force based on pipe-soil contact characteristics[J]. Chinese Journal of Geotechnical Engineering, 2017, 39(2): 244-249(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201702009.htm [7] Shimada H, Khazaei S, Matsui K. Small diameter tunnel excavation method using slurry pipe-jacking[J]. Geotechnical & Geological Engineering, 2004, 22(2): 161-186. http://www.onacademic.com/detail/journal_1000034828634710_bf4c.html [8] Shou K, Yen J, Liu M. On the frictional property of lubricants and its impact on jacking force and soil-pipe interaction of pipe-jacking[J]. Tunnelling and Underground Space Technology, 2010, 25(4): 469-477. doi: 10.1016/j.tust.2010.02.009 [9] 王双, 夏才初, 葛金科. 考虑泥浆套不同形态的顶管管壁摩阻力计算公式[J]. 岩土力学, 2014, 35(1): 159-166, 174. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201401024.htmWang S, Xia C C, Ge J K. Formulae of lateral friction resistance for pipe-jacking considering different form of mud screen[J]. Rock and Soil Mechanics, 2014, 35(1): 159-166, 174(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201401024.htm [10] 张鹏, 谈力昕, 马保松. 考虑泥浆触变性和管土接触特性的顶管摩阻力公式[J]. 岩土工程学报, 2017, 39(11): 2043-2049. doi: 10.11779/CJGE201711012Zhang P, Tan L X, Ma B S. Formulae of frictional resistance considering lubrication mudthixotropy and pipe-soil contact characteristics[J]. Chinese Journal of Geotechnical Engineering, 2017, 39(11): 2043-2049(in Chinese with English abstract). doi: 10.11779/CJGE201711012 [11] Reilly C C, Orr T L L. Physical modelling of the effect of lubricants in pipe jacking[J]. Tunnelling and Underground Space Technology, 2017, 63(3): 44-53. http://www.sciencedirect.com/science?_ob=ShoppingCartURL&_method=add&_eid=1-s2.0-S0886779815300419&originContentFamily=serial&_origin=article&_ts=1482721546&md5=7831267501d6bd0c12e3176bfeab27e2 [12] 周浩, 周千淼, 谈力昕, 等. 考虑注浆作用的矩形顶管竖向土压力计算模型研究[J]. 地质科技通报, 2021, 40(2): 125-130. doi: 10.19509/j.cnki.dzkq.2021.0201Zhou H, Zhou Q M, Tan L X, et al. Vertical soil pressure calculation model of rectangular box jacking considering grouting effect[J]. Bulletin of Geological Science and Technology, 2021, 40(2): 125-130(in Chinese with English abstract). doi: 10.19509/j.cnki.dzkq.2021.0201 [13] 李剑, 张鹏, 李志宏. 顶管施工润滑泥浆压力引起的土体附加应力计算[J]. 地质科技情报, 2016, 35(2): 23-27. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201602006.htmLi J, Zhang P, Li Z H. Calculation of soil additional stress induced by lubrication mud pressure during pipe jacking constructions[J]. Geological Science and Technology Information, 2016, 35(2): 23-27(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201602006.htm [14] Stein D, Möllers K, Bielecki, R. Microtunneling installation and renewal of nonman-size supply and sewage lines by the trenchless construction method[M]. Berlin: Ernst& Sohn, 1989. [15] 黄吉龙. 大口径玻璃钢夹砂顶管室内试验与数值分析[D]. 上海: 上海交通大学, 2007.Huang J L. Experimental and numerical analysis of large diameter class reinforced plastic mortar pipe-jacking[D]. Shanghai: Shanghai Jiaotong University, 2007(in Chinese with English abstract). [16] 李超, 钟祖良, 刘新荣, 等. 复杂接触条件下超长距离混凝土顶管-围岩摩擦特性及现场卡管处置验证研究[J]. 岩石力学与工程学报, 2019, 38(6): 1197-1208. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201906011.htmLi C, Zhong Z L, Liu X R, et al. Experimental study on the complex contact frictional property of an ultra-long distance large section concrete pipe jacking with the verification of on-sitesolution of pipe stuck[J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(6): 1197-1208(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201906011.htm [17] 中华人名共和国住房和城乡建设部. GB50007-2011建筑地基基础设计规范[S]. 北京: 中国建筑工业出版社, 2012.The Ministry of Construction of China & General Administration of Quality Supervision. GB50007-2011 Code for design of building foundation[S]. Beijing: China Architecture & Building Press, 2012(in Chinese). [18] Sitharam T G, Nimbkar M S. Micromechanical modelling of granular materials: Effect of particle size and gradation[J]. Geotech. Geol. Eng., 2000, 18(2): 91-117. doi: 10.1023/A:1008982027109 [19] 赵文, 李天亮, 韩健勇, 等. 砾砂与混凝土管界面剪切力学特性试验[J]. 东北大学学报: 自然科学版, 2020, 41(3): 424-429, 456. https://www.cnki.com.cn/Article/CJFDTOTAL-DBDX202003022.htmZhao W, Li T L, Han J Y, et al. Experiment of shear properties on the interface between gravelly sand and concrete pipe[J]. Journal of Northeastern University: Natural Science Edition, 2020, 41(3): 424-429, 456(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DBDX202003022.htm [20] 徐肖峰, 魏厚振, 孟庆山, 等. 直剪剪切速率对粗粒土强度与变形特性的影响[J]. 岩土工程学报, 2013, 35(4): 728-733. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201304019.htmXu X F, Wei H Z, Meng Q S, et al. Effects of shear rate on shear strength and deformation characteristics of coarse-grained soils in large-scale direct shear tests[J]. Chinese Journal of Geotechnical Engineering, 2013, 35(4): 728-733(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201304019.htm -

下载:

下载: