Dynamic response charactertstics of long petroleum pipelines extending along mountain ridge under strong earthquake

-

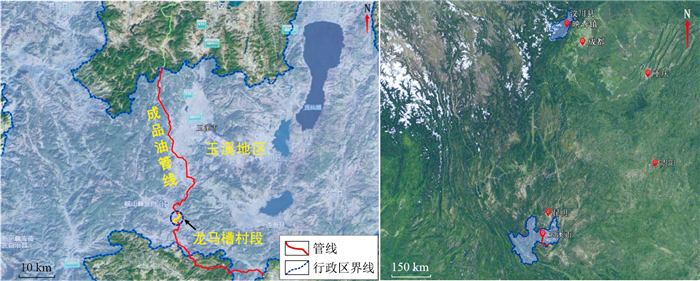

摘要: 沿山脊走向的长输油气管道在我国西部山区常有分布,强震作用下其动力响应直接关系到管道的安全运营,实际管道工程建设中亟需相关研究结果提供指导。依托云南玉溪龙马槽村段此类输油管道工程,考虑山坡的工程地质特征,对管道与坡体进行整体三维数值建模,采用有限差分方法FLAC3D进行数值模拟,基于汶川地震波,计算得到了水平地震加速度峰值、震后等典型时刻的管道位移、轴力、剪力和弯矩及坡体稳定性等地震动力响应特征。结果表明,管道内力最大值出现于震后时刻,地震作用使管道轴力达到较高水平,而剪力与弯矩值的量级仅占最大轴力的约1%;竖向地震波对管道内力影响较小,管道受力的不利部位出现在其与断层交界附近。地震过程中管道水平方向存在较多的弹性变形,竖向则存在较多的塑性变形,管道累计变形是影响其内力的主要因素,管道内力最大值出现于震后时刻。Abstract: There are many long petroleum pipelines extending along mountain ridges in the mountainous areas of western China.Dynamic responses of the pipelines under strong earthquake have significant effect on their safe service ability.It is necessary for the related investigations to provide guidance for practical construction of the pipeline projects.In terms of a typical section of this kind of oil pipelines at Longmacao village, Yusi, Yunnan, a pipeline-slope 3D numerical simulation model is established considering engineering geology conditions of the slope.Further, dynamic responses of the pipeline including its displacement, axial force, shear force and bending moment as well as overall stability of the pipeline-slope system are computed using FLAC3D program with inputting Wenchuan seismic wave, and the seismic responses at some typical moments such as the moment at peak value of the horizontal acceleration and after the earthquake are specifically obtained.The results show that internal forces of the pipeline reach their maximum values after the earthquake, and the axial force gets high level under strong earthquake but the shear force and bending moment are in small level with about 1% magnitude of the former.Besides, vertical seismic wave has little effect on internal forces of the pipeline, and the position of the maximum internal forces is near the intersection of the pipeline and fault.During strong earthquake, the pipelines appear mainly elastic and plastic deformation in the horizontal and vertical direction, respectively.The accumulated deformation is the major factor to influence internal forces of the pipelines, whose maximum occurs at the moment after the earthquake.

-

Key words:

- petroleum pipeline /

- mountain ridge /

- strong earthquake /

- dynamic response /

- numerical simulation

-

表 1 龙马槽村段管道-坡体数值模型的主要物理力学参数

Table 1. Main physical and mechanical parameters of the pipeline-slope system in Longmacao village

弹性模量/GPa 泊松比 重度/(kN·m-3) 内摩擦角/(°) 黏聚力/MPa 抗拉强度/MPa 砂质板岩 10 0.3 26 40 0.5 3 断层1 5 0.3 22 40 0.25 0 板岩 20 0.3 27 45 1 7 断层2 1 0.3 22 30 0.15 0 黏土夹砂 2 0.3 23 30 0.30 0.4 白云岩 14 0.3 26 35 0.42 3 管体材料 205 0.2 78 - - 300 -

[1] 孙绍平, 韩阳. 生命线地震工程研究述评[J]. 土木工程学报, 2003, 36(5): 97-104. doi: 10.3321/j.issn:1000-131X.2003.05.017Sun S P, Han Y. State-of-the-art of the research on lifeline earthquake engineering[J]. China Civil Engineering Journal, 2003, 36(5): 97-104(in Chinese with English abstract). doi: 10.3321/j.issn:1000-131X.2003.05.017 [2] Lee D H, Kim B H, Lee H, et al. Seismic behavior of a buried gas pipeline under earthquake excitations[J]. Engineering Structures, 2009, 31(5): 1011-1023. doi: 10.1016/j.engstruct.2008.12.012 [3] 陈前, 晏鄂川, 黄少平, 等. 基于样本与因子优化的黄冈南部地区地质灾害易发性评价[J]. 地质科技通报, 2020, 39(2): 175-185. https://dzkjqb.cug.edu.cn/CN/abstract/abstract9987.shtmlChen Q, Yan E C, Huang S P, et al. Susceptibility evaluation of geological disasters in southern Huanggang based on samples and factor optimization[J]. Bulletin of Geological Science and Technology, 2020, 39(2): 175-185(in Chinese with English abstract). https://dzkjqb.cug.edu.cn/CN/abstract/abstract9987.shtml [4] Newmark N M, Hall W J. Pipeline design to resist large fault displacement[C]. Michigan: Proceedings of US Conference on Earthquake Engineering, 1975. [5] Kennedy R P, Darrow A W, Williamson R A. Fault movement effects on buried oil pipeline[J]. Journal of Transportation Engineering, 1977, 3(5): 617-633. http://gateway.proquest.com/openurl?res_dat=xri:pqm&ctx_ver=Z39.88-2004&rfr_id=info:xri/sid:baidu&rft_val_fmt=info:ofi/fmt:kev:mtx:article&genre=article&jtitle=Journal%20of%20Transportation%20Engineering&atitle=Fault%20movement%20effects%20on%20buried%20oil%20pipeline [6] Chiou Y J, Chi S Y, Chang H Y. A study of buried pipeline response to fault movement[J]. Journal of Pressure Vessel Technology, 1994, 116(1): 36-41. doi: 10.1115/1.2929556 [7] 刘爱文, 张素灵, 胡聿贤, 等. 地震断层作用下埋地管线的反应分析[J]. 地震工程与工程振动, 2002, 22(2): 22-27. doi: 10.3969/j.issn.1000-1301.2002.02.004Liu A W, Zhang S L, Hu Y X, et al. A method for analyzing response of buried pipeline due to earthquake fault movement[J]. Earthquake Engineering and Engineering Vibration, 2002, 22(2): 22-27(in Chinese with English abstract). doi: 10.3969/j.issn.1000-1301.2002.02.004 [8] Datta T K. Seismic response of buried pipelines: A state-of-the-art review[J]. Nuclear Engineering and Design, 1999, 192(2): 271-284. http://www.onacademic.com/detail/journal_1000034151554510_0161.html [9] 王绍杰, 朱庆杰, 刘英利, 等. 管土相互作用下埋地管道的抗震性能研究[J]. 世界地震工程, 2007, 23(1): 47-50. doi: 10.3969/j.issn.1007-6069.2007.01.010Wang S J, Zhu Q J, Liu Y L, et al. Research on earthquake resistance of buried pipeline under pipe-soil interaction[J]. Chinese Journal of World Earthquake Engineering, 2007, 23(1): 47-50(in Chinese with English abstract). doi: 10.3969/j.issn.1007-6069.2007.01.010 [10] 冯启民, 郭恩栋. 跨断层埋地管道抗震试验[J]. 地震工程与工程振动, 2000, 20(1): 56-62. doi: 10.3969/j.issn.1000-1301.2000.01.008Feng Q M, Guo E D. Aseismic analysis test of buried pipe crossing fault[J]. Earthquake Engineering and Engineering Vibration, 2000, 20(1): 56-63(in Chinese with English abstract). doi: 10.3969/j.issn.1000-1301.2000.01.008 [11] 张志超, 王进廷, 徐艳杰. 跨断层地下管线振动台模型试验研究(Ⅰ): 试验方案设计[J]. 土木工程学报, 2011, 44(11): 93-98. https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201111018.htmZhang Z C, Wang J T, Xu Y J. Shaking table test for cross-fault buried pipelines(Ⅰ): Model design[J]. China Civil Engineering Journal, 2011, 44(11): 93-98(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201111018.htm [12] 张志超, 王进廷, 徐艳杰. 跨断层地下管线振动台模型试验研究Ⅱ: 试验成果分析[J]. 土木工程学报, 2011, 44(12): 116-125. https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201112017.htmZhang Z C, Wang J T, Xu Y J. Shaking table test for fault-crossing buried pipelines(Ⅱ): Test result[J]. China Civil Engineering Journal, 2011, 44(12): 116-125(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201112017.htm [13] 李立云, 刘晓晓, 杜修力, 等. 埋地管道地震响应的数值仿真模型分析[J]. 地震工程与工程振动, 2015, 35(6): 108-115. https://www.cnki.com.cn/Article/CJFDTOTAL-DGGC201506015.htmLi L Y, Liu X X, Du X L, et al. Analysis on numerical simulation model for seismic response of a buried pipeline[J]. Earthquake Engineering and Engineering Vibration, 2015, 35(6): 106-113(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DGGC201506015.htm [14] 陈金龙, 罗文行, 窦斌, 等. 涿鹿盆地三维多裂隙地质模型地温场数值模拟[J]. 地质科技通报, 2021, 40(3): 22-33. https://dzkjqb.cug.edu.cn/CN/abstract/abstract10135.shtmlChen J L, Luo W X, Dou B, et al. Numerical simulation of geothermal field in a three-dimensional multi-fractured geological model of Zhuolu Basin[J]. Bulletin of Geological Science and Technology, 2021, 40(3): 22-33(in Chinese with English abstract). https://dzkjqb.cug.edu.cn/CN/abstract/abstract10135.shtml [15] 杜修力, 韩俊艳, 李立云. 长输埋地管道振动台试验设计中相似关系的选取[J]. 防灾减灾工程学报, 2013, 33(3): 246-252. https://www.cnki.com.cn/Article/CJFDTOTAL-DZXK201303003.htmDu X L, Han J Y, Li L Y. Selection of shaking table test similarity relations for long-distance buried pipeline[J]. Journal of Disaster Prevention and Mitigation Engineering, 2013, 33(3): 246-252(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DZXK201303003.htm [16] Vazouras P, Karamanos S A, Dakoulas P. Finite element analysis of buried steel pipelines under strike-slip fault displacements[J]. Soil Dynamics and Earthquake Engineering, 2010, 30(11): 1361-1376. doi: 10.1016/j.soildyn.2010.06.011 [17] Vazouras P, Karamanos S A, Dakoulas P. Mechanical behavior of buried steel pipes crossing active strike-slip faults[J]. Soil Dynamics and Earthquake Engineering, 2012, 41: 164-180. doi: 10.1016/j.soildyn.2012.05.012 [18] Kaya E S, Uckan E, O'Rourke M J, et al. Failure analysis of a welded steel pipe at Kullar fault crossing[J]. Engineering Failure Analysis, 2017, 71: 43-62. doi: 10.1016/j.engfailanal.2016.10.004 [19] 岳庆霞, 吴华勇, 李杰. 管土动力相互作用分析[J]. 地震工程与工程振动, 2007, 27(3): 132-136. https://www.cnki.com.cn/Article/CJFDTOTAL-DGGC200703021.htmYue Q X, Wu H Y, Li J. Analysis of pipe-soil dynamic interaction[J]. Earthquake Engineering and Engineering Vibration, 2007, 27(3): 132-136(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-DGGC200703021.htm [20] 孙钢柱, 祁晓昱. 承插式水泥管-土非一致激励模拟试验研究[J]. 世界地震工程, 2011, 27(3): 53-59. https://www.cnki.com.cn/Article/CJFDTOTAL-SJDC201103009.htmSun G Z, Qi X Y. Research on numerical simulation of adapting-form cement pipe-soil non-uniform excitation test[J]. World Earthquake Engineering, 2011, 27(3): 53-59(in Chinese with English abstract). https://www.cnki.com.cn/Article/CJFDTOTAL-SJDC201103009.htm [21] Xiao S G, Feng W K, Zhang J J. Analysis of the effects of slope geometry on the dynamic response of a near-field mountain from the Wenchuan earthquake[J]. Journal of Mountain Science, 2010, 7(4): 353-360. http://www.cqvip.com/QK/87799X/201004/36071472.html [22] Itasca Consulting Group. FLAC3D 5.0 manual[M]. Minneapolis, USA: Itasca Consulting Group, 2012. -

下载:

下载: